Chongqing PurePath Green Technology Co.,LTD.

- Annual Revenue 100000000-20000000 USD

- Employees 50~100

- Year Established 2011

- Manufacturer, Exporter, Trading Company, Seller

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Dehydration Decolor Used Oil Regeneration Plant Prevent Fouling Heating

Used Oil Dehydration Decolor To Commerical Stand Diesel Waste Oil Regeneration Plant

Product Description

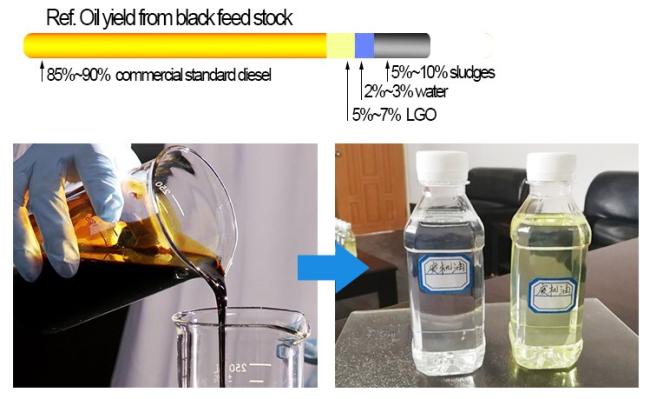

We are proud to present you with our PPGT-LP waste oil cracking distillation plant which is combined with dozens of our newest technologies to delivery you with the excellent quality of diesel oil out of different type of car engine and machinery engine or industrial waste oil, tire and plastic pyrolysis oil and sludge oils.

As the manufacturer, PurePath owns professional engineering team to provide constructively project proposal according to different waste oil feedstock or standard requirement of the final oil products. In order to get a more clear and purier distillates, genuine continuous fractional distillation and further PurePath exclusive desulfurization system are optional. Before the process of distillation begins, we also highlight the equally important steps prior to cracking distillation. A concurrent pretreatment solid removal and dehydration and defueling process could also upgrade the quality and purity of oil products and increase the working efficiency.

Technical Process Description of Waste Oil Regeneration Plant

- Technical Process Description

- Flocculation and sedimentation to removal solid impurity and some organic acid compounds.

- Refining tower to strip light gas oil and water from feed black oil.

- Adsorption and desulfurization.

- Catalytic cracking distillation.

- Fractional genuine continuous distillation to generate quality diesel.

- Refining for good color or even water color diesel.

- Feed of waste oil is pumped into the blending tank.

- Syngas and fixed gas decolor, deodor.

Plant Specification Of Waste Oil Regeneration Plant

| Model No. | PPGT-LP-1 | PPGT-LP-2 | PPGT-LP-3 | PPGT-LP-4 | PPGT-LP-5 | PPGT-LP-6 | PPGT-LP-7 | PPGT-LP-8 |

| Items. | ||||||||

| Process Capacity MAX. | 2 TPD | 5 TPD | 10 TPD | 15 TPD | 20 TPD | 30 TPD | 50 TPD | 100 TPD |

| Heating Power | 17KGS LPG/20KGS FUEL OIL/230KWH/PER TON OF WASTE OIL | |||||||

| Power Consumption | 25KWH PER TONS OF WASTE OIL | |||||||

| Working Pressure | Atoms pressure | |||||||

| Heating Method | Fuel Oil/Natural Gas/LPG/Electricity | |||||||

| Heating Temp. | 30-420℃ | |||||||

| Voltage | 220/380/415V 50/60HZ | |||||||

| Noise | ≤60dB | |||||||

Performances of recycled diesel from Waste Oil Regeneration Plant

Parameters Of Diesel Product From Waste Oil Regeneration Plant

| PARAMETER | UNIT | METHOD | RESULT | ||||

| Flash Point PMCC | °C | ASTM D93-18a | 61 °C | ||||

| Water Content | ppm | ASTM D 6304-07 | 81 | ||||

| Lubricity, corrected diameter (ws 1.4) at 60°C § | µm | ASTM D6079-18 | 485 | ||||

| Ash Content | % wt | ASTM D 482-13 | <0.001 | ||||

| Sulphur Content | %wt | ASTM D4294-16e1 | 0.0046 | ||||

| Density at 15°C | kg/m3 | ASTM D1298-12b | 835.5 | ||||

| Pour Point | °C | ASTM D97-12 | -21 | ||||

| Cetane Index | ASTM D 4737-10 | 55.8 | |||||

| Viscosity Kin at 40°C | cSt | ASTM D445-17a | 3.8 |

High Lights Of Waste Oil Regeneration Plant

Real Fractionation Column

Precisely calculated data of Nos. & distances of column plates, plus the PPGT patented packings to ensuring the optimal effect of gas-liquid mass transfer process (the multiple contacts b/t gas phase and liquid phase in the rectifying column), completely separate the light HC out of your feedstock to get precise cuts of diesel fractions. Ensuring the high flash point and cetane number of produced diesel fuel.

Factory Show

Customer Visiting

Successful Project Show

Please do not hesitate to contact me.