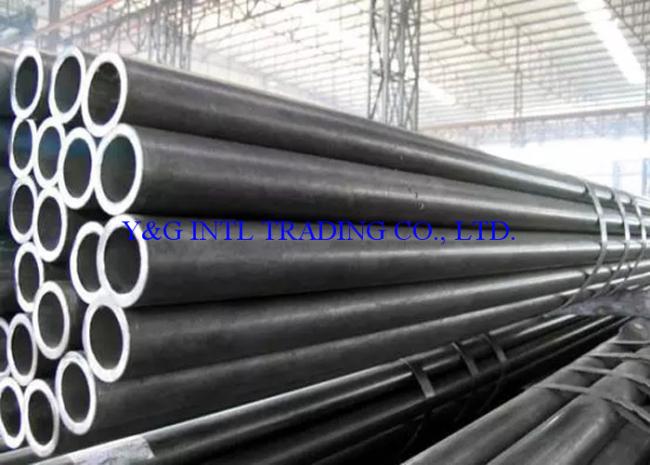

A333 Gr9 Seamless Carbon Steel Tube For Low Temperature Pressure Vessel

A333 Gr9 Seamless Carbon Steel Industrial Tube For Low-Temperature Pressure Vessel and Heat Exchanger Pipe 141.3 * 15.88mm

ASTM A333 Grade 9 Standard covers seamless and welded steel pipe for low temperature service. The ASTM A333 Grade 9 steel involved is similar to AISI 4032 low alloy steel. ASTM A333 Grade 9 pipe shall be made by the seamless or welding process with the addition of no filler metal in the welding operation. ASTM A333 Grade 9 covers seamless and welded steel pipe for low temperature service. The Grade 9 alloy steel involved is similar to AISI 4032 low alloy steel.

Product Standard: GB/T18984-2003,ASTM A333,ASME SA333

Main steel grades: 16MnDG,10MnDG,09DG,09Mn2VDG,06Ni3MoDG,ASTM A333Gr1,A333Gr3,A333Gr4,A333Gr6,A333Gr7,A333G8,A333Gr9,A333Gr10,A333Gr11

Application: for low temperature pressure vessel pipes of -45 °C ~ -195 °C and low temperature heat exchanger pipes.

Chemical Requirements & Mechanical Properties:

| Standard | GB/T18984-2003 | ||||||||||

| Chemical Components (%) | |||||||||||

| Grades | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | Al |

| 16MnDG | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | -- | -- |

| 10MnDG | ≤0.13 | 0.17-0.37 | ≤1.35 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | ≤0.07 | -- |

| 09DG | ≤0.12 | 0.17-0.37 | ≤0.95 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | ≤0.07 | -- |

| 09Mn2VDG | ≤0.12 | 0.17-0.37 | ≤1.85 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | ≤0.12 | -- |

| 06Ni3MoDG | ≤0.08 | 0.17-0.37 | ≤0.85 | ≤0.025 | ≤0.025 | -- | 2.5-3.7 | -- | 0.15-0.30 | ≤0.05 | -- |

| ASTM A333 | A333Gr1 | ≤0.30 | -- | 0.40-1.06 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | -- |

| A333Gr3 | ≤0.19 | 0.18-0.37 | 0.31-0.64 | ≤0.025 | ≤0.025 | -- | 3.18-3.82 | -- | -- | -- | -- |

| A333Gr4 | ≤0.12 | 0.18-0.37 | 0.50-1.05 | ≤0.025 | ≤0.025 | 0.44-1.01 | 0.47-0.98 | 0.40-0.75 | -- | -- | 0.04-0.30 |

| A333Gr6 | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.025 | ≤0.025 | -- | -- | -- | -- | -- | -- |

| A333Gr7 | ≤0.19 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | -- | 2.03-2.57 | -- | -- | -- | -- |

| A333Gr8 | ≤0.13 | 0.13-0.32 | ≤0.90 | ≤0.025 | ≤0.025 | -- | 8.40-9.60 | -- | -- | -- | -- |

| A333Gr9 | ≤0.20 | -- | 0.40-1.06 | ≤0.025 | ≤0.025 | -- | 1.60-2.24 | 0.75-1.25 | -- | -- | -- |

| A333Gr10 | ≤0.20 | 0.10-0.35 | 1.15-1.50 | ≤0.030 | ≤0.015 | ≤0.15 | ≤0.25 | ≤0.015 | ≤0.50 | ≤0.12 | ≤0.06 |

| A333Gr11 | ≤0.10 | ≤0.035 | ≤0.60 | ≤0.025 | ≤0.025 | ≤0.50 | 35.0-37.0 | -- | ≤0.50 | -- | -- |

| Standard | Grades | TS(Mpa) | YS(Mpa) | Elongation(%) | |

| vertical | horizontal | ||||

|

GB/T1898 -2003 |

16MnDG | 490-665 | ≥325 | ≥30 | -- |

| 10MnDG | ≥400 | ≥240 | ≥35 | -- | |

| 09DG | ≥385 | ≥210 | ≥35 | -- | |

| 09Mn2VDG | ≥450 | ≥300 | ≥30 | -- | |

| 06Ni3MoDG | ≥455 | ≥250 | ≥30 | -- | |

| ASTM A333 | A333Gr1 | ≥380 | ≥205 | ≥35 | ≥25 |

| A333Gr3 | ≥450 | ≥240 | ≥30 | ≥20 | |

| A333Gr4 | ≥415 | ≥240 | ≥30 | ≥16.5 | |

| A333Gr6 | ≥415 | ≥240 | ≥30 | ≥16.5 | |

| A333Gr7 | ≥450 | ≥240 | ≥30 | ≥22 | |

| A333Gr8 | ≥690 | ≥515 | ≥22 | -- | |

| A333Gr9 | ≥435 | ≥315 | ≥28 | -- | |

| A333Gr10 | ≥550 | ≥450 | ≥22 | -- | |

| A333Gr11 | ≥450 | ≥240 | ≥18 | -- |

Heat Treatment Requirements:

All seamless and welded pipe shall be treated to control their microstructure by the following methods: Normalizing per A 333/A 333M-05 section 4.2.1.1; section 4.2.1.2 or section 4.2.1.3 Quenched and Tempered per A 333/A 333M – 05 section 4.2.2.1 Double Normalized and Tempered per A 333/A 333M – 05 section 4.2.2.2

Mark: As required.

Inspection and Test: chemical composition test, mechanical properties test(tensile, yield, elongation), process properties test(flatting, flaring, bending, hardness, impact, etc.), appearance and size test, non-destructive inspection test, hydrostastic test.

Delivery status: Annealed, normalized, normalized+Tempered, etc.

Surface treatment: oil impregnation, paint, passivation, phosphating, shot blasting etc.

Packing: Exporting package/wooden box /as requirement.