Jiangsu Shengman Drying Equipment Engineering Co., Ltd

- Annual Revenue >10,700,000 USD

- Employees >50

- Year Established 2011

- Manufacturer

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Vacuum Oil Sludge Oil Loam Hollow Paddle Dryer

Chinese Factory Vacuum Hollow Sludge Blade Drying Equipment For Oil Sludge Oil Loam

Product introduction

The product can indirectly heat or cool paste, granular, powdery and slurry materials, and can complete unit operations such as drying, cooling, heating, sterilization, reaction, low temperature combustion, etc. The special wedge-shaped agitated heat transfer blade in the equipment has high heat transfer efficiency and self-cleaning function of heat transfer surface.

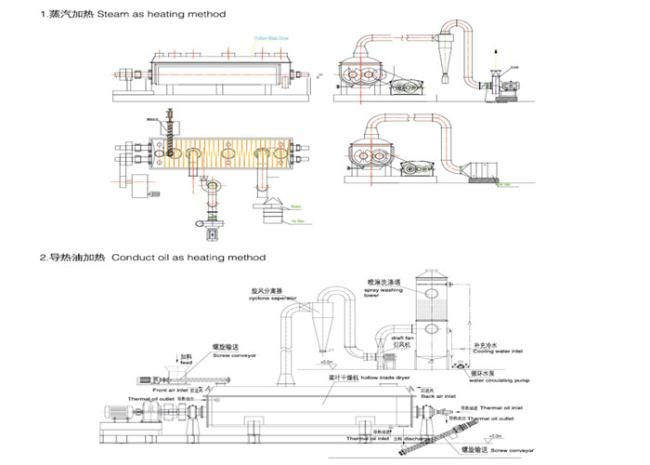

HEAT SOURCES(Temperature at 180°C - 250°C)

Heating by Steam Steamenters the hollow shaft through a rotary joint and is evenly distributed to all paddles. Condensate is removed with each revolution. Heating by Hot Oil (thermal fluid) Hot oil (thermal fluid) enters and exits the hollow shaft through a rotary joint. Pressure from the supply pump forces liquid through the hollow paddles.

Technical parameters

| Model | KJG-2.7 | KJG-24 | KJG-52 | KJG-81 | KJG-110 |

| Heat transfer area | 2.7 | 24 | 52 | 81 | 110 |

| effective volume | 0.06 | 1.53 | 3.96 | 6.43 | 9.46 |

| revolution | 15-30 | 10-20 | 10-20 | 5-15 | 5-10 |

| power | 2.2 | 11 | 30 | 55 | 95 |

| width of dryer body | 306 | 1118 | 1474 | 1828 | 2210 |

| total width | 736 | 1474 | 1854 | 2286 | 2668 |

| length of dryer body | 1956 | 3454 | 5258 | 6020 | 6122 |

| total length | 2972 | 6147 | 8306 | 9678 | 9880 |

| distance between feeding and disharging | 1752 | 3150 | 4954 | 5562 | 5664 |

| height in center | 380 | 1066 | 1220 | 1220 | |

| total height | 762 | 2032 | 2464 | 2668 | |

| steam inlet | (2) 3/4 | (2) 1 | (2) 11/2 | (2) 11/2 | (2) 2 |

| water outlet | (2) 3/4 | (2) 1 | (2) 11/2 | (2) 11/2 | (2) 2 |

Application

This dryer is widly used in pharmaceutical industry, foodstuff industry, chemical industry and etc. Especially be sutiable for the following materials:

1. Pulpiness, paste-like mixture or powder materials.

2. Thermal sensitive material which required to be dried at lower temperature.

3. Material that are easy to oxidize or explode and the material that have strong irritative or toxic.

4. Material that required recoverying solvet.

Performance characteristics

Low energy consumption of pulp leaf dryer: due to indirect heating, there is no large amount of air to take away heat, and the outer wall of the dryer is provided with insulation layer, which only needs 1.2kg steam to evaporate 1kg water for slurry materials.

Low cost of blade dryer system: the unit effective volume has a huge heat transfer surface, which shortens the processing time and reduces the equipment size. It greatly reduces the building area and building space.

A wide range of processing materials: using different thermal media, it can handle both heat sensitive materials and materials requiring high temperature treatment. Common media are: steam, heat transfer oil, hot water, cooling water, etc.

It can be operated continuously or intermittently, and can be used in many fields.

Small environmental pollution: do not use carrying air, dust material entrainment is small. The evaporation of solvent is very small, which is easy to handle. It can be used for contaminated materials or solvent recovery.

FAQ

Q1. What is the advantage about your company? A1. Our company has professional team and professional production line.

Q2. Why should I choose your products? A2. Our products are high quality and low price.

Q3. Any other good service your company can provide? A3. Yes,we can provide good after-sale and fast delivery.