Stainless Steel ASTM A268 TP405 Stainless Steel SMLS Tube

Stainless Steel ASTM A268 TP405 Stainless Steel SMLS Tube

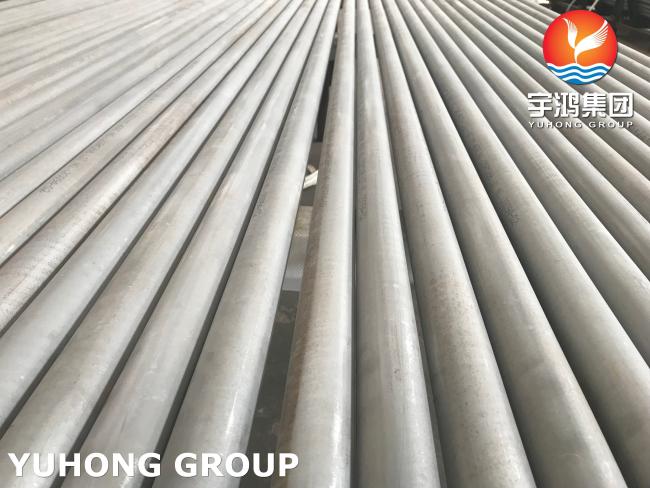

We are YUHONG GROUP,one of the biggest manufactures of stainless steel & duplex steel & alloy steel tubes and pipes in China. With development more than 33 years, we have accumulated a great many clients all around the world and Yuhong products also won the great praise among the customers.

Description

SUS 405 Tubes has same corrosion resistance of Type 410 Steel. Type 405 Pipes is used in situations where more weldability is desired than Type 410. However, Type 405 Tubes can be easily machined due to its soft and ductile characteristics.

Chemical Composition of ASTM A268 TP405 Stainless Steel Pipes

| C % | Mn % | P % | S % | Si % | Cr % | Ni % | Al % |

| 0.08 max | 1.00 max | 0.04max | 0.03 max | 1.00 max | 11.5-14.5 | 0.50 max | 0.10-0.30 |

Mechanical Properties of ASTM A268 TP405 Stainless Steel Pipes

| Tensile Strength, Mpa | Yield Strength, MPa | Elongation, % | Hardness, HB |

| 415 min | 205 min | 20 min | 207 max |

Specification

| Specifications | ASTM A268 / SA 268 |

| Dimensions | ASTM, ASME and API |

| Size | 1/4″ (6.25mm) to 8″ (203mm), WT 0.02″ (0.5mm) to 0.5″(12mm) |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Specialized in | Large Diameter Size |

| Length | Single Random, Double Random & Cut Length. |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| End | Plain End, Beveled End, Treaded |

ASTM A268 TP405 SS U Bend Tube Features

‘U’ bending is done by cold working process.

‘U’ bending is done to the required radius as per customer drawings.

The bend portion and six inch leg is stress relieved by resistance heating.

The radius is checked for its OD and wall thinning with the recommended specification.

The physical properties and micro-structure is checked at three different position.

Visual inspection for waviness and cracks is done with Dye Penetrant Test.

Each tube is then hydro tested at the recommended pressure to check for leakage.

Cotton ball test is done to check the ID cleanliness of the tube.

Inert gas (Argon) is passed through it at the required flow rate to avoid oxidation in ID.

Thereafter pickled, dried, marked and packed.

All procedure is strictly followed as per TEMA “C” and ASTM A-688.