CEBE GROUP HK CO.,LTD

- Annual Revenue 20 million-30 million USD

- Employees 10~50

- Year Established 2013

- Manufacturer, Distributor/Wholesaler, Agent, Exporter, Trading Company, Seller

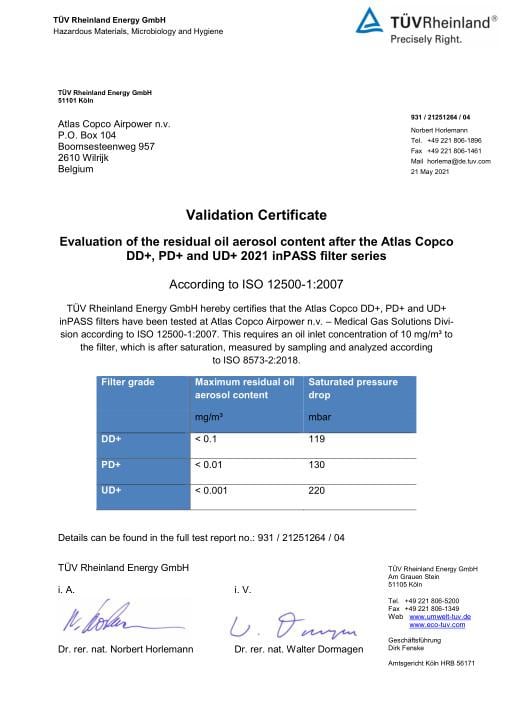

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

22kw Atlas Copco Water Injected Screw Compressors AQ 22 VSD Oil Free

22KW ATLAS COPCO AQ-22 VSD OIL-FREE WATER INJECTED SCREW COMPRESSORS

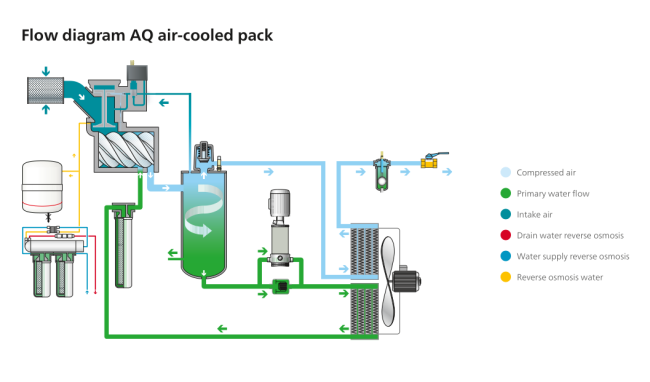

POWERFUL OIL-FREE AIR

When it comes to clean, oil-free compressed air, you cannot afford to compromise on quality. Over the past decades, Atlas Copco has pioneered

oil-free water-injected screw technology, resulting in a broad range of compressors delivering 100% oil-free, clean air. Setting the standard through

ISO 8573-1 CLASS 0 certification, the AQ meets your need for pure oil-free air while offering best in class energy efficiency.

Water-injected screw element

• Highly energy-efficient thanks to low temperatures.

• Water-lubricated, grease-free bearings.

• In-house design and manufacturing.

• Working pressure up to 13 bar.

Water filter

• Ensuring a constant supply of clean water.

• The filtration capability equals 10 micron throughout the filter’s lifetime.

Elektronikon ®Graphic

Advanced Elektronikon ®Graphic control and monitoring system, designed for integration in a (remote) process control system.

Sound insulated canopy

No separate compressor room is required as the sound insulated canopy allows for installation in most working environments.

Electronic no-loss water drain

• Ensures constant removal of condensate.

• Manual integrated bypass for effective condensate removal in case of power failure.

• Integrated with compressor’s Elektronikon ® with warning/alarm features.

PROVEN TECHNOLOGY

At the heart of the new AQ range is a unique water-injected screw element working highly efficient near isothermal compression. The polymer ceramic rotors with their optimized rotor profile are supported by water-lubricated bearings, ensuring that no oil whatsoever can contaminate the compression element, thereby producing pure oil-free air.

Rotors

A highly efficient compression process is achieved thanks to high quality polymer mould ceramic rotors with optimum profiling. The combination

of corrosion-free, high efficiency raw material and water lubrication results in a longer lifespan.

Element housing

Strength and durability are ensured as a result of the aluminium bronze element housing without risk of corrosion within the element.

Element bearings

The use of hydrodynamic bearings ensure long life as no physical contact is made within the bearing itself, it simply glides on a film of water removing the need for any oil or grease lubrication.

Specifications

| COMPRESSOR TYPE |

Tyoe | Max. working pressure (bar(e)/psig) WorkPlace |

Capacity FAD* | Installed motor power | Noise level** |

Weight WorkPlace |

Weight WorkPlace Full Feature |

|||

| pack | Full Feature | l/s | m³/min | cfm | kw | dB(A) | kg | kg | ||

| AQ22 VSD | air-cooled | 13/188 | 12.75/185 | 22-66 | 1.3-4.0 | 47-140 | 22 | 70 | 740 / 1631 | 800 / 1764 |

| water-cooled | 13/188 | 12.75/185 | 22-66 | 1.3-4.0 | 47-140 | 22 | 70 | 740 / 1631 | 800 / 1764 | |

(2) Mean sound pressure level according to ISO2151, uncertainty 3 dB(A).

(1) Unit performance measured according to ISO1217 Annex E, Edition 4, 2009.