CEBE GROUP HK CO.,LTD

- Annual Revenue 20 million-30 million USD

- Employees 10~50

- Year Established 2013

- Manufacturer, Distributor/Wholesaler, Agent, Exporter, Trading Company, Seller

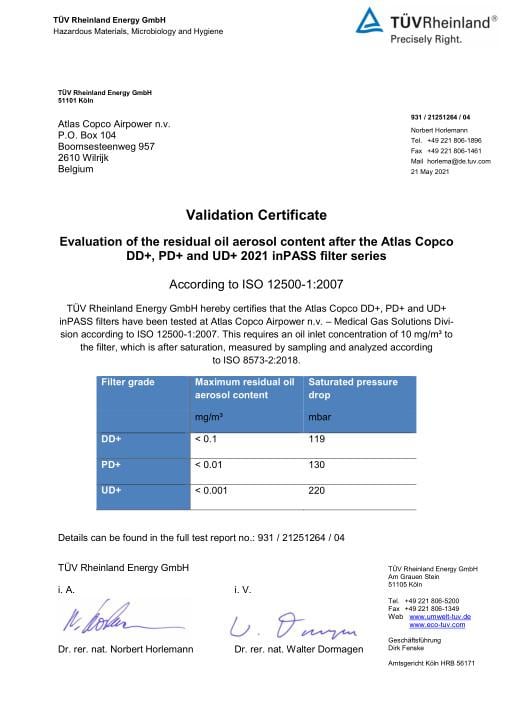

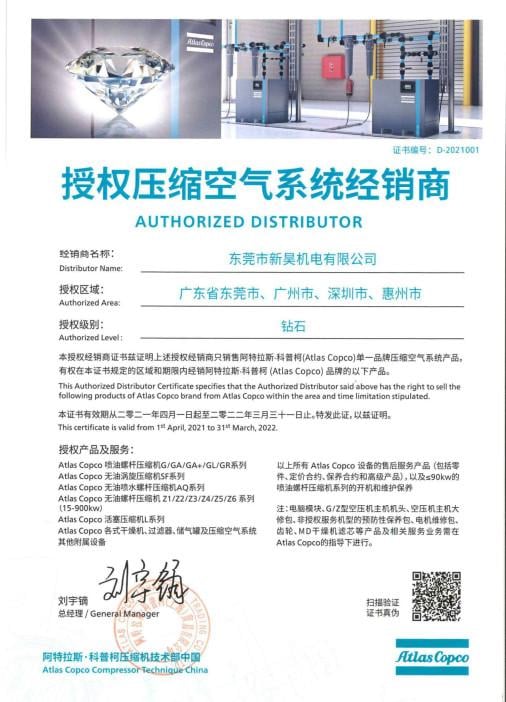

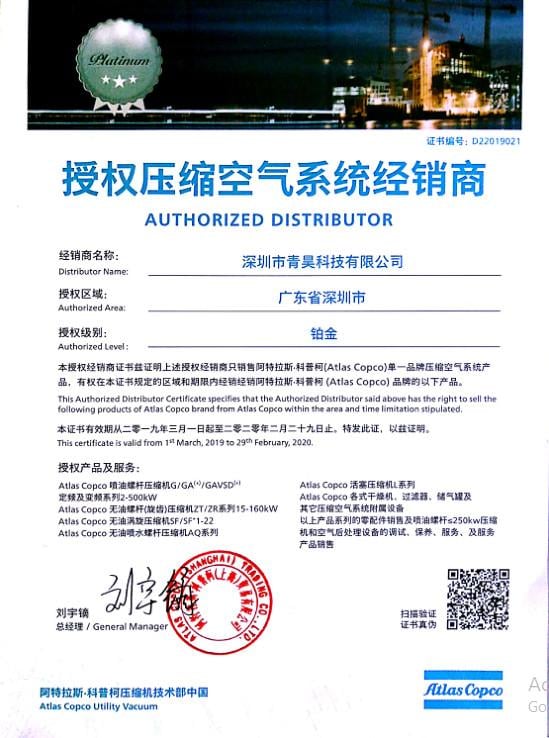

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

GA220+ Atlas Copco GA Series 50Hz 5.5 Bar 220kw Aluminum Alloy Material

GA220+50Hz Air Compressor

HIGHEST RELIABILITY, LOWEST OPERATING COSTS

The shortest route to maximize your profitability is to minimize your operational cost. As energy consumption is the major factor (up to 70%) of a compressor’s lifecycle cost, the Atlas Copco GA 160+-250 compressors are designed to help you achieve significant savings. The compressors provide high-quality compressed air to meet your requirements even in the most demanding applications.

SPECIFICATIONS

| TYPE | Working pressure | Capacity FAD (1) |

Installed motor power |

Noise level (2) | Weight | ||||

| Standard | Standard | Standard | |||||||

| bar(e) | psig | l/s | m³/min | cfm | kW | dB(A) | kg | lb | |

| GA 220+ - 5.5 bar | 5.5 | 80 | 837 | 50.2 | 1773 | 220 | 78 | 5099 | 11241 |

| GA 220+ - 7.5 bar | 7.5 | 109 | 744 | 44.7 | 1576 | 5099 | 11241 | ||

| GA 220+ - 8.5 bar | 8.5 | 123 | 671 | 40.2 | 1421 | 5099 | 11241 | ||

| GA 220+ - 10 bar | 10 | 145 | 612 | 36.7 | 1296 | 4954 | 10922 | ||

| GA 220+ - 14 bar | 14 | 203 | 492 | 29.6 | 1042 | 4954 | 10922 |

||

INCREASE YOUR SAVINGS WITH ENERGY RECOVERY

The Kyoto directives and the continuing depletion of traditional energy sources mean that businesses throughout the world are making commitments to significantly reduce overall energy consumption. Through innovative products and solutions, Atlas Copco helps you achieve your goals in this area. When it comes to compressed air production – where energy costs can constitute 70% of total lifecycle costs

– saving energy can also lead to substantial cost savings.

Integrated heat exchanger

Air compression creates heat that is normally wasted in the coolers. Energy recovery systems designed by Atlas Copco enable the recovery of most of this heat. Recovery of energy from the shaft input of the compressor can be up to 94% of the compressor shaft power. The heat is directly usable as a source of energy in the form of hot water (85-90°C/185- 194°F). The main module of the recovery system is built into the compressor. The investment needed to link the hot oil circuit from the compressor to the existingwater circuit is relatively modest and the time needed before seeing payback from your investment is generally very short.