GUANGDONG HWASHI TECHNOLOGY INC.

- Annual Revenue 6000000-8000000 USD

- Employees 150~200

- Year Established 2001

- Manufacturer, Importer, Exporter, Trading Company, Seller

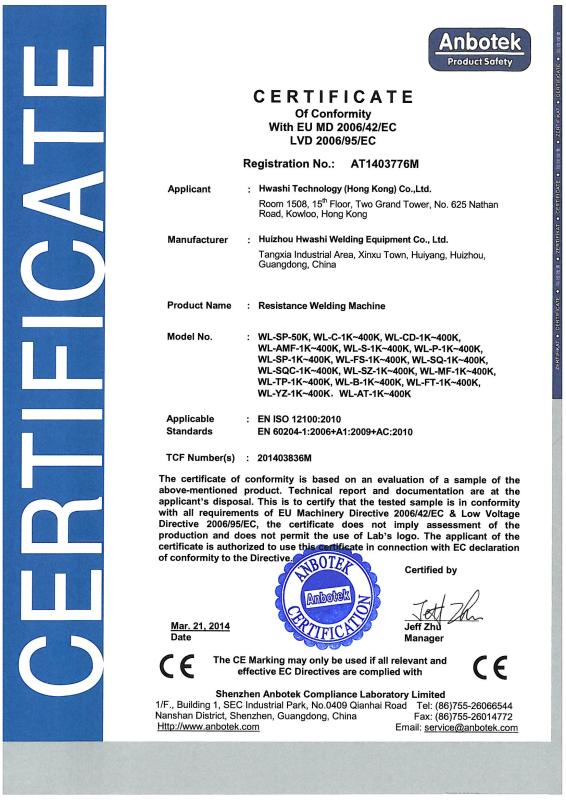

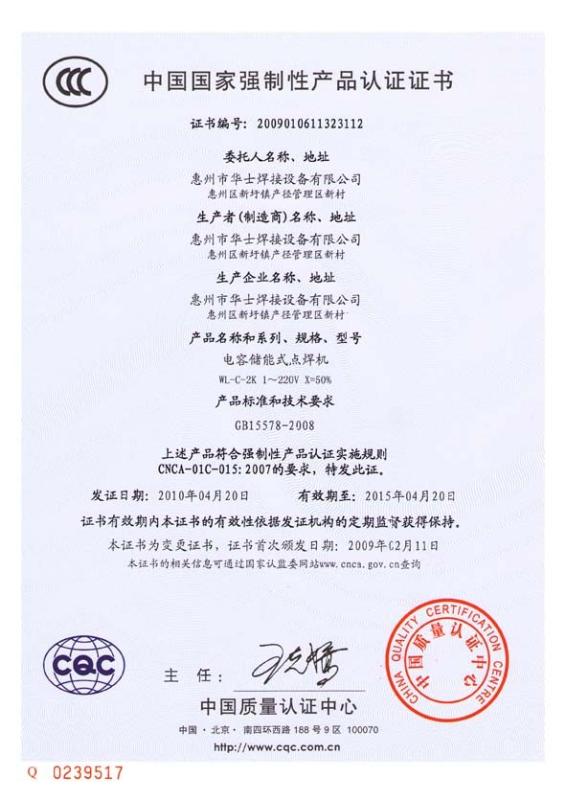

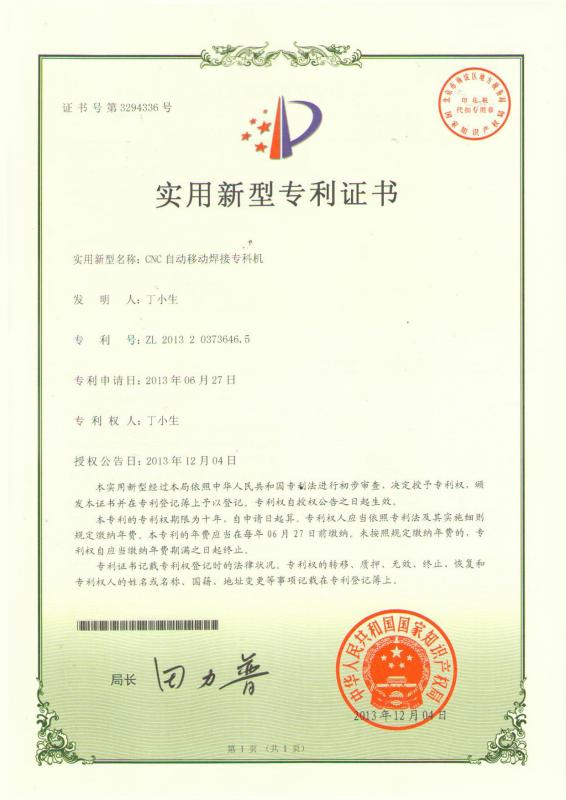

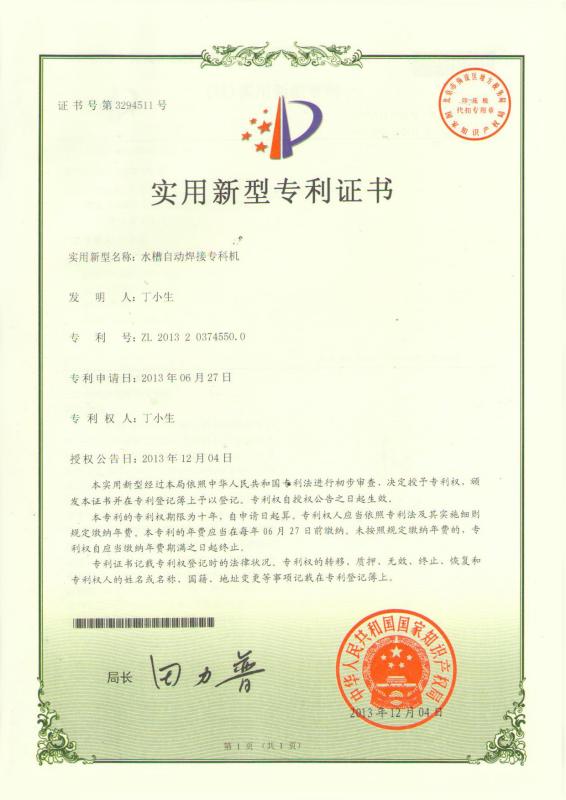

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Automobile Seat Frame Parts MIG Welding Robot

Project Background: Automobile Seat Frame Parts Welding Robot Unit (Applied in one of the famous automobile parts company in Guizhou, China)

Customer Requirement:

1. Use robot to replace labor force for welding. Manual loading and unloading of product. One time fixing of the product onto the fixture.

2. Workpiece material: iron steel, wall thickness: 3-10mm; Size:

3. High welding consistency requirement. Deep welding penetration requirement. The welding should be very strong.

Solutions:

1. The complete welding robot system includes 1 set of HS-R6-08 1.4m arm length robot, 1 set of 350A MIG welding machine, 1 set of automatic anti-collision welding gun, 1 set of double station one axis positioner and two sets of fixed table and fixture, 1 set of welding gun cleaner, etc.

2. In order to guarantee the stability and consistency of welding quality, we suggest to equip with welding gun cleaner device.

3. Automatic welding is carried out by a six-axis robot MIG welder. The cylinders or fast clamps are used to fix the position of the product with the lever principle to ensure the positioning requirements of automatic welding of the robot, so as to ensure that it can be welded to each part of the product. According to the requirements of production efficiency, one set of double station one axis positioner and two sets of fixed table are designed, one for loading and unloading of the workpiece, one for welding.

Workflow:

1) Manual loading of the workpiece to the fixture in Station 1 positioner;

2) Start welding;

3) The robots and welding machines will do welding on the workpiece according to the presetting program;

4) Welding completed;

5) While the station 1 is being welded, station 2 is being loaded and unloaded the work piece synchronously.

6) Cycle working

Application Effect

1. Double-station layout can realize long time continuous welding, welding efficiency and welding quality has been significantly improved;

2. The positioner and fixed table realizes the workpiece clamping at one time, and automatically realizes the alternating welding of the product, so that the deformation is effectively controlled.

3. This machine can achieve automatic welding with manually loading material. It can also improve the welding quality and welding efficiency. Whats more, it can reduce the production cost. The problem of unstable quality and low production efficiency caused by pure manual operation has been solved.

4. Robot replace manual welding. Welding industry is a high-risk industry, high temperature, arc light and welding smoke have a certain impact on the physical and mental health of workers;

5. It is an inevitable trend to use robots to replace welding robots in welding, which is not only the promotion of the market, but also the requirement of technological upgrading.