INFINITE AUTOMATION CO ., LIMITED

- Employees 50~100

- Year Established 2006

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Vacuum Type SMT Assembly Line PCB Loader For Double Sided Boards

Vacuum Type SMT Assembly Line PCB Loader For Double Sided Boards

Vacuum Type PCB Loader, SMT PCB Vacuum Loader for double-sided boards, High-quality and Durable SMT Link Conveyors

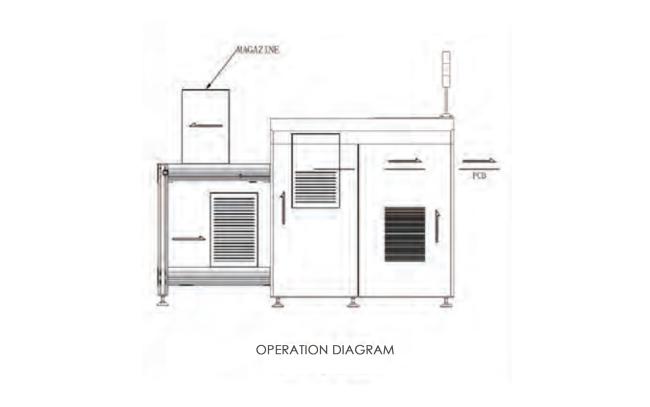

Vacuum Type PCB Loader is the equipment used in the SMT production line. The main function of this machine is for automatic loading of double-sided boards and transceiver board. Infinite Vacuum Type PCB Loader is designed with a multifunctional electrical circuit and program design to able to provide stable performance and ensure smooth of the feeding plate PCB. Made of durable materials with a stable integral casting lifting platform structure design to improve the stability of the equipment. Infinite Vacuum Type PCB Loader is available for different PCB sizes. We also accept customized design.

Features:

- Special aluminum alloy institutions, more clearly understand the state of MAGAZINE operation

- The stable integral casting lifting platform structure design has improved the stability of the equipment

- Multifunctional electrical circuit and program design, stable performance, ensure smooth of the feeding plate PCB

- The upper part of the bin has 4 kinds of PITCH selection, which can set the step distance of the feeding plate PCB

- The LED tricolor working indicator is controlled by a 7-inch color human-machine interface

- A universal positioning mechanism is adopted for the suction nozzle positioning, and the absorption bits can be adjusted according to the characteristics of the PCB board

- The board part of the PCB on the suction plate has the function of lifting and unlifting

- The material box is transmitted by the plastic strip of the flat plate

- Adjustable push plate speed control

- Three-point positioning, upper and lower pneumatic clamping, ensure the location of the box is accurate

- The push plate protection system ensures that the PCB board will not be damaged and the process loss will be reduced

- The standard SMEMA communication interface can be connected with other automation devices

| TECHNICAL PARAMETERS | |

| Description | This unit is used for automatic loading operation of double-sided boards and transceiver board |

| No. of magazine | Upper Conveyor: 1 magazine, Lower Conveyor: 2magazine |

| Indexing pitch | 10.20.30.40mm or specify |

| Maximum PCBs capacity | 400pcs (0.6mm thick PCB) |

| Cycle time | Approx. 12 seconds or specify |

| Power supply | AC1P110V/220V |

| Power | Max 300VA |

| Air pressure | 4-6bar,30ltr/min max |

| Transport height | 900±20mm (or customized) |

| Transport direction | From left to right or right to left |

| SPECIFICATIONS | ||||

| Model | Dimension (L*W*H MM) | PCB size (MM) | Rack size (L*W*H MM) | Weight (KG) |

| VL-M-TN | 1800*865*1250 | 50*80-330*250 | 355*320*563 | 200 |

| VL-L-TN | 2220*945*1250 | 50*80-445*330 | 460*400*563 | 240 |

| VL-LL-TN | 2450*1110*1250 | 50*80-530*390 | 535*460*563 | 280 |

| VL-XL-TN | 2450*1250*1250 | 50*80-530*460 | 535*530*563 | 320 |