Stability Temperature Humidity Climate Walk In Test Chamber For Car Computer Phone LCD Lamp

Stability Temperature Humidity Climate Walk In Test Chamber For Car/Computer /Phone/ LCD/Lamp

Application:

Hognjin Programmable Walk - In Environmental Temperature Humidity Stability Climatic Test Chamber is perfectly meet the large size test application that require high temperature and high humidity. The chamber is constructed with structural steel, the steady structure able to test the large components and products. Various optional function available for different test standard and requirement.

Must meet the requirements of international standards (IEC, JIS, GB, MIL...) to achieve international measurement procedure consistency (including test procedures, conditions, methods)

Features:

1. Energy efficient technology, more stable, durable longevity.

2. Steel structure, Stainless steel interior cabinet, easy to clean.

3. Test data logging output with USB memory stick.

4. RS485 and Ethernet remote control.

5. Alarm notification via phone available.

6. Programmable

Test limit

This test equipment is suitable for:

Electrical, electronic products, components, components and materials are stored in high and low temperature environments

Adaptability tests for storage, transportation and use.

This test equipment is prohibited:

Testing or storage of flammable, explosive, volatile materials

Testing or storage of corrosive substance samples

Testing or storage of biological samples

Testing or storage of samples of strong electromagnetic emission sources

Volume, size and weight

| Size(cm) | BT-6 | BT-8 | BT-12 | BT-16 | BT-20 | BT-24 | BT-28 |

| Inner box (D*H*W) | 200*200*150 | 200*200*200 | 200*200*300 | 200*200*400 | 200*200*500 | 200*200*600 | 200*200*700 |

| Outer box (D*H*W) | 220*250*270 | 220*250*320 | 220*250*420 | 220*250*520 | 220*250*620 | 220*250*720 | 220*250*720 |

| Performance | |

| Test environmental conditions | The ambient temperature is +25 ° C, the relative humidity is ≤ 85%, and there is no sample in the test chamber. |

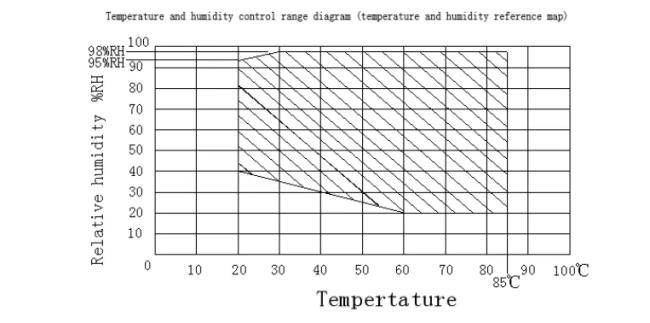

| High temperature range | 85°C(150°C) |

| Low temperature range | A: +25 °C B:0°C C:-20°C :-40°C E:-60°C F:-70°C) |

| Humidity range | 30-80%(Customize 10% - 98%) |

| Temperature fluctuation | ±0.5°C |

| Temperature distribution accuracy | ±2.0°C |

| Humidity fluctuation | ±5% R.H. (damp heat only) |

| Humidity distribution accuracy | ±5.0%. (damp heat only) |

| Load situation | The test space is no more than three-quarters of the total space and there is no heat. |

| testing method | GB/T 5170.2-1996 temperature test equipment |

| GB/T 5170.5-1996 Damp heat test equipment (damp heat type only) |

1.Thermal insulation structure

Outer wall material: high quality stainless steel 304 / cold rolled steel plate painting

Inner wall material: high quality stainless steel 304

Box insulation material: flame retardant fireproof rigid polyurethane foam

Door insulation material: flame retardant fireproof rigid polyurethane foam.

Centrifugal fan, return air mode: air blow on equipment, return air

Heater, evaporator, water supply and drain, temperature sensor.

Window 250x320x40mm 3-layer vacuum layer

Explosive handle

Door hinge: SUS #304

Box light PL light 11W

Lead hole: φ50mm 1

Single door, left open, handle on the right hand side. With observation window 250*320 mm, lighting,

Window frame/door frame anti-condensation electric heating device

5. Control panel Controller display, over temperature protection setter

6. Mechanical room Refrigeration unit, water tray, drain hole

7. Distribution control cabinet, distribution board, exhaust fan

8. Heater Heating system: finned heat pipe type stainless steel electric heater heating air circulation mode

9. Humidifier Boiler type humidification system, circulating through the air duct system.

10. Power cable hole and drain hole are located on the back of the cabinet

1.Condenser Water-cooled shell tube heat exchanger.

2. Expansion system Refrigeration system (capillary) for capacity control.

3. Evaporation condenser Stainless steel brazed plate heat exchanger.

4. Refrigerator control mode The controller of the control system automatically adjusts the operating conditions of the refrigerator according to the test conditions.

Evaporate the pressure regulating valve.

Compressor return air cooling circuit.

5. Temperature and humidity controller

It adopts the micro-computer color LCD display touch screen, Chinese wide angle of view, high contrast function temperature and humidity can be programmed at the same time, with 100 groups of programs 1000 segments of memory, each segment 530Hour59Min, can be arbitrarily divided Settings, and With multiple sets of PID control functions.

6. Controller Specifications

Accuracy: temperature ±0.1 °C+1 digit, humidity ±1% R.H+1digit

Resolution: temperature ± 0.01 ° C, humidity ± 0.1% R. H.

Temperature slope: 0.1 ~ 9.9 can be set.

With upper and lower limit standby and alarm function.

Temperature and humidity input signal dry and wet ball PT100x2.

7 sets of P.I.D control parameter settings, P.I.D automatic calculation.

Dry and wet balls are automatically corrected.

Cooling System

Compressor overheating

Compressor overcurrent

Compressor overpressure

Condensing fan overheating

Compressor oil pressure protection

The floor is flat and well ventilated

No strong vibration around the device

No strong electromagnetic field around the device

No flammable, explosive, corrosive substances and dust around the equipment

Appropriate use and maintenance space is left around the equipment, as shown below:

A: not less than 10cm

B: not less than 60cm

C: not less than 60cm

D: not less than 120cm

(only for wet heat equipment with water purifier)

Flow rate ≥200kg/h,

The pressure is 0.1 MPa to 0.25 MPa.

Tap water meets the sanitary standards for drinking water in GB 5749-1985.

Note: DN15 male connector for pure water machine.

Company instrotruction

BOTO GROUP Ltd. is a private enterprise integrating r&d, production, OEM and sales of scientific and technological equipment manufacturing. Proficient in the production, development and upgrading of various non-standard instruments and automatic instruments. The factory covers an area of 26,666 square meters, headquartered in Shanghai, has several offices in China, the factory annual output of about 2000 sets of equipment. Since the establishment of the company, the company is committed to providing customers with quality products and services, and has been praised by customers.

In the domestic market, we have many end customers, third-party testing institutions, research institutes, leading enterprises in different industries, and some agents. For the overseas market, we hope to find more general agents, distributors and importers to cooperate together.

The factory has the ability to calibrate, and the customer can also designate a third party organization to calibrate and issue a calibration report.

Some foreign customers have equipment leasing business, we only provide new equipment sales, no leasing business.