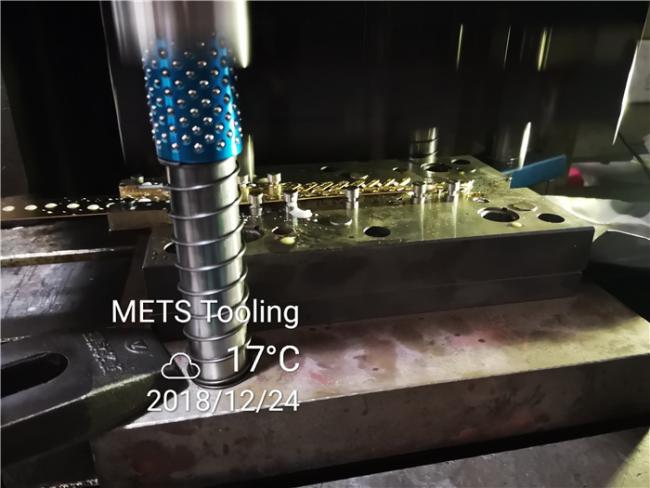

Sheet Metal Stamping Dies Press For Copper N Brass Connector Parts

Sheet metal die press for copper n brass connector parts

ETS Stamping works with a complete range of precision stamping materials to satisfy even the most demanding specifications. We service a wide range of industries with a complete array of materials from stainless to plastics. Our equipment is capable of handling a wide variety of thicknesses and finishes. We offer complete traceability and documentation when needed. We give our customers peace of mind that they are getting the best materials possible for their project.

Metal Stamping Materials

We offer a variety of different material options including:

· Iron

· Aluminum

· Stainless steel

· Copper

· Brass

· Specialty Metals

Stamping Specifications

· Stock thickness ranges from .0015 to .25+

· Stock width ranges from 1/4" up to 23-1/2"

· Ferrous and non-ferrous

· Pre-Plated and finished

At METS Stamping, our customers come first, and our core values of listening to you and delivering a high-quality product the first time and every time to bring added value to every part we produce. That’s what Power Satisfaction is all about.

| Material Available | Carbon steel/Stainless Steel/Aluminum/Brass/Copper/Bronze/High Temp Metals/Inconel/Monel/Spring Steel 65Mn |

| Surface Treatment | Polishing/Passivating/Sandblasting/Laser engraving/ Zinc Plating/Oxide/Nickel Plating/Chrome Plating/Carburized/Heat Treatment/Power Coated/Clear Anodized/Color Anodized/Sandblast Anodized/Chemical Film/Brushing/Polishing/Chroming |

| Custom metal stamping methods | Progressive/compound/Blanking/Drawing/Bending/Coining/Forming |

| Additional Services | Blanking/Piercing/Forming/Drawing/Progressive tooling/Deburring/Grinding/Honing/Assembling |

| Tolerance(+/-) | ±0.02mm |

| Lead time | 2-4 weeks |

FAQ

Q: What’s your manufacture capability?

---- We use Sodick/Charmilles to frabricate die inserts,dimension we can do is +/-0.002mm.

Q: Can you make all the dimensions are according to our design/samples?

---- We can guarantee that all the dimensions are made according to your drawing/sample.Please notice that dimension tolerence we can do is +/-0.003mm.

Q: What’s your advantage compare with other supplier’s on the market?

---- We are stamping factory,have a team contains die design,making,maintance and stamping production.We know how important the good mold for stamping production.So the metal stamping parts is better that other factories.

---- All our engineers are with more than 10 years working experience.They are more professional on precision stamping field.

Visit Website