Jiangsu Shengman Drying Equipment Engineering Co., Ltd

- Annual Revenue >10,700,000 USD

- Employees >50

- Year Established 2011

- Manufacturer

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Food Yeast 380v Drum Drying Equipment Steam Heating

Factory direct selling drum roller dryer for brewer's yeast/ feed yeast/food yeast

Descriptions of Drum Dryer for brewer's yeast/ feed yeast/food yeast:

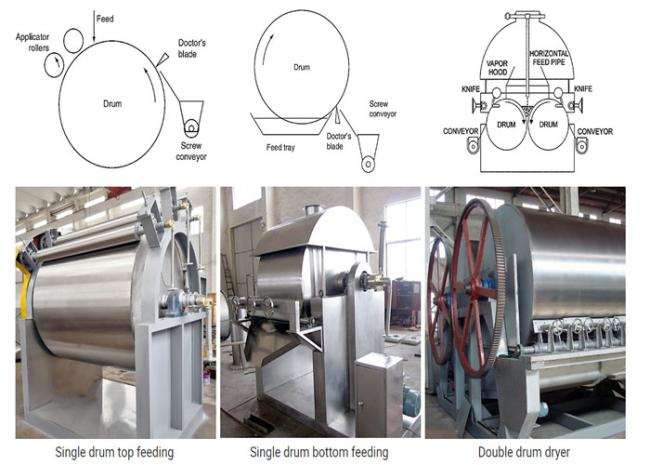

Drum dryer is a kind of rotating continuous drying equipment with internal heating conducting-style. Certain thickness of materials film attach to the drum from material liquid vessel under the drum. Heat is transferred to the internal wall of the cylinder through pipes and then to the external wall and to materials film, to evaporate the moisture in materials film so as to dry materials. Dried products are then scraped off by the blade fitted on the surface of the cylinder, fall down to the spiral conveyor under the blade, and are conveyed, collected and packed.

Working principle of roller scraper dryer

The operation principle of TG series cylinder type Rotary Drum Roller dryer is to let that the materials in liquid or thick liquid state form the thin film on the surface of the cylinder heated through steam or other thermal carrier. For one turn of the cylinder, the film will complete the drying and the product will be removed through the scraper. The exposed surface of the cylinder will contact the materials again to form the film and carry out the drying, It is suitable for drying liquid raw material or sticky material in chemical industry, dyestuff industry, pharmaceutical industry, foodstuff industry, and metallurgy industry and so on.

Technical parameters

| size | size of cylinder(mm) | heating area(㎡) | drying capacity(kg/h) | power kw | weight |

| HG-600 | 600*800 | 1.12 | 40-70 | 1.1 | 850 |

| HG-700 | 700*1000 | 1.65 | 60-90 | 2.05 | 1210 |

|

HG-800 |

800*1200 | 2.26 | 90-130 | 3.75 | 1700 |

| HG-1000 | 1000*1400 | 3.30 | 130-190 | 4.75 | 2100 |

| HG-1200 | 1200*1500 | 4.24 | 160-250 | 4.75 | 2650 |

| HG-1400 | 1400*1600 | 5.28 | 210-310 | 6.25 | 3220 |

| HG-1600 | 1600*1800 | 6.79 | 270-400 | 6.25 | 4350 |

| HG-1800 | 1800*2000 | 8.48 | 330-500 | 8.6 | 5100 |

| HG-1800A | 1800*2000 | 10.6 | 420-630 | 8.6 | 6150 |

Features of Drum Dryer for brewer's yeast/ feed yeast/food yeast:

1.High heat efficiency. The principle of heat transfer of the cylinder dryer is heat conduction and the conducting direction keeps identical in the whole operation circle. Except heat loss of end cover and radiation loss, all heat can be used for evaporation of wet materials on the wall the cylinder. The efficiency can reach 70-80%.

2. Large operation elasticity and wide application. Various drying factors of the dryer can be adjusted, such as concentration of feeding liquid/thickness of material film, temperature of heating medium, rotating speed of the drum etc. which can change drying speed of the under dryer. As these factors have no interrelations each other, it brings great convenience to dry operation and makes it applicable to dry various materials and to meet different requirements of production.

3. Short drying period. The drying period of materials is normally 10 to 300 seconds, so it is suitable for heat-sensitive materials. It also can be pressure reducing operated if it is put in vacuum vessel.

4. Fast drying rate. As film of materials coated on the wall of the cylinder is very thin. Normal, thickness is 0.3 to 1.5mm, plus directions of heat and mass transmitting are identical, the evaporation strength on the surface of the film can be 20-70 kg.H2O/m2.h.

Applications of Drum Dryer for brewer's yeast/ feed yeast/food yeast:

It is suitable for drying liquid raw materials or thick liquid in chemical, dyestuff, pharmaceutical, foodstuff, metallurgy and so on industries.

Pre-service:

As a good and rich experience supplier, we should offer customer the best quality and best price of the machine. We do something as following:

(1). introduce the suitable product to the customer in detail

(2). answer the question raised by customer carefully

(3). make the suitabe project as the customer requirement

(4). make sure the machine is suitable for the material

Sale service:

In order to fulfill the contract smoothly, establish a good cooperative relationship, here's are several points what we must do.

(1). ensure product with high quality and pre-commissioning before delivery

(2). delivery on time

(3). provide full set of documents as customer’s requirements

After-sale service:

Provide considerate services to minimize customers’ worries.

(1). Assist customers to prepare for the first construction scheme.

(2). Install and debuging the drying equipment.

(3). Train the first-line operators.

(4). Exame the drying equipment.

(5). Take initiative to eliminate the troubles rapidly.

(6). Provide technical support.

(7). Establish long-term and friendly relationship with all my customers.

Service commitment:

We provide customers 12-months warranty to make sure the machine work well, and always keep certain inventory level of spare parts, which means the replacements can be sent to you timely. At the same time, we send every customer a preferential and reasonable quotation.

Visit Website