Jiangsu Shengman Drying Equipment Engineering Co., Ltd

- Annual Revenue >10,700,000 USD

- Employees >50

- Year Established 2011

- Manufacturer

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Contact Parts 304 LPG25 25000rpm Centrifugal Spray Dryer In Food Industry

LPG series 100L Capacity Spray Drying Machine for Instant Coffee Powder

Product Description

Spray drying is the most wide applied process in liquid process shaping and drying industry.The drying technology is most suitable for producing solid powder or practical products from liquid material,such as :solution,emulsion,suspension and pumpable paste states.For this reason,the particle size and distribution of the final products,residual water contents,mass density and the particle shape must meet the precise standard,spray drying is one of the most desired technologies.

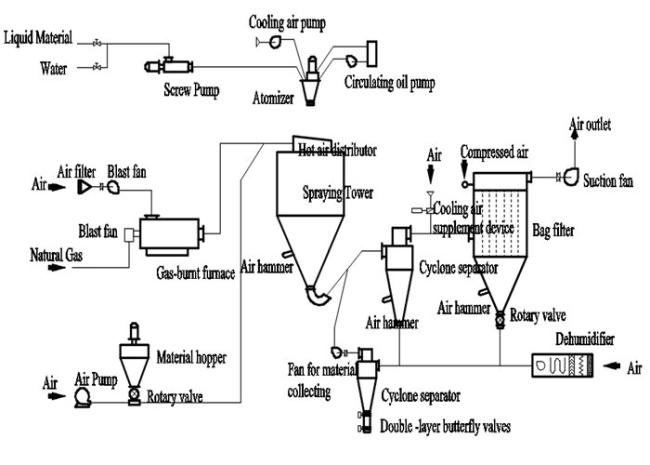

Working Principle

Main Features

1) Particle size control: The dry particle size can be easily controlled by atomization of the liquid feed and the design of the hot gas inlet. This spray dryer can typically produce between 30 to 500 micron average particle size, in a bell shaped distribution.

2) The evaporative cooling of product: The heat and mass transfer during drying occurs in the air and vapor films surrounding the droplet. This protective envelope of vapor keeps the particle at the saturation temperature. As long as the particle does not become "bone-dry", evaporation is still taking place and the temperature of the solids will not approach the dryer outlet temperature.

3) Short residence time: The surface area produced by atomization of the liquid feed enables a short gas residence time, ranging from 3-10 seconds depending upon the application, which permits spray drying without thermal degradation.

4) Flow properties of dry product: The shape of most spray dried particles is spherical, which provides for fluid-like flow properties. This makes many downstream operations, such as packaging, pressing, filtering, and handling easier and less costly.

5) Size design of drying chamber: The size of drying chamber is specially designed to prevent droplets sticking to the inner wall, dried powder accumulating on the cone part and guarantee enough residence time.

Technical parameters

| Model | PLG | |||||

| 5 | 25 | 50 | 100 | 150 | 200-2000 | |

| inlet temperatyre ℃ | 140-350 automatically controlled | |||||

| outlet temperatyre ℃ | 80-90 | |||||

| Max water evaporation capacity kg/h | 5 | 25 | 50 | 100 | 150 | 200-2000 |

| centrifugal spraying nozzle transmission mode | compressed air transmission | mechaical transmission | ||||

| rotation speed (r.p.m) | 25000 | 18000 | 18000 | 18000 | 15000 | 8000-15000 |

| spraying desc diameter (mm) | 50 | 100 | 120 | 140 | 150 | 180-340 |

| max electric heating power (kw) | 9 | 36 | 63 | 81 | 99 | settled by customer |

| overall dimensions | 1.8*0.93*2.2 | 3*2.7*4.26 | 3.7*3.2*5.1 | 4.6*4.2*6 | 5.5*4.5*7 | depends on tryer |

| dried powder collection | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 |

Applications

. Chemical industry

Sodium fluoride(potassium), alkaline dyestuff and pigment, dyestuff intermediate, compound fertilizer, formic silicic acid, catalyst, sulphuric acid agent, amino acid, white carbon and so on.

. Plastics and resin

AB, ABS emulsion, uric acid resin, phenloic aldehyde resin, urea-formaldehyde resin, formaldehyde resin, polythene, polychloroprene and etc.

. Food industry

Fatty milk powder, protein, cocoa milk powder, substitute milk powder, egg white(yolk), food and plant, oats, chicken juice, coffee, instant dissoluble tea, seasoning meat, protein, hydrolysate and so forth.

FAQ

Q: How can I visit your factory?

A: Our company is in Changzhou city, and it is very near Shanghai city. It takes about 1 hour to get to Changchou. Or we can even visit you in Shnghai.

Q: What’s the quality of your products?

A: Our products come with best quality, and passed CE certification. And exported to lots countries around the world, such as Australia, Malaysia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured with the quality absolutely.

Q: What to do if the machine has a problem?

A: 24 hours timely response of mail and phone calls. If the parts broken belong to non-artificial factors within 12 months, we offer free replacement. If beyond 12 months, customers should bear the freight back and forth and accessories cost.

Q: How long is the warranty of your equipment?

A: One year.

Q: What is your payment term?

A: Our usual payment term is: 30% TT in advance, 70% TT before shipment. Other ways can also be received after we both sides discussion and agreement.

Q: Does your price include freight?

A: Our usual price is based on FOB Shanghai. If you request CIF, please give us your delivery port, and we will give you CIF price.

Visit Website