DSTHERM INDUSTRIAL LIMITED

- Annual Revenue 45,000,000-50,000,000 USD

- Employees 100~200

- Year Established 2004

- Manufacturer, Importer, Exporter, Seller

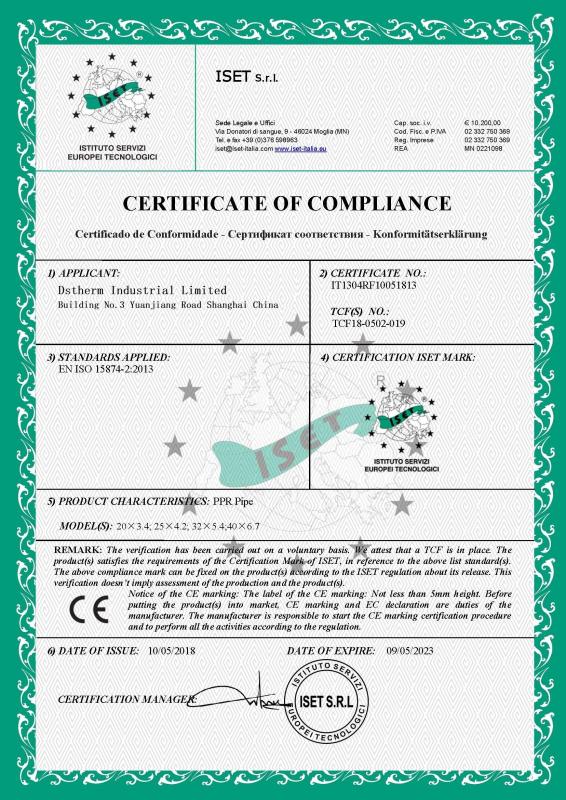

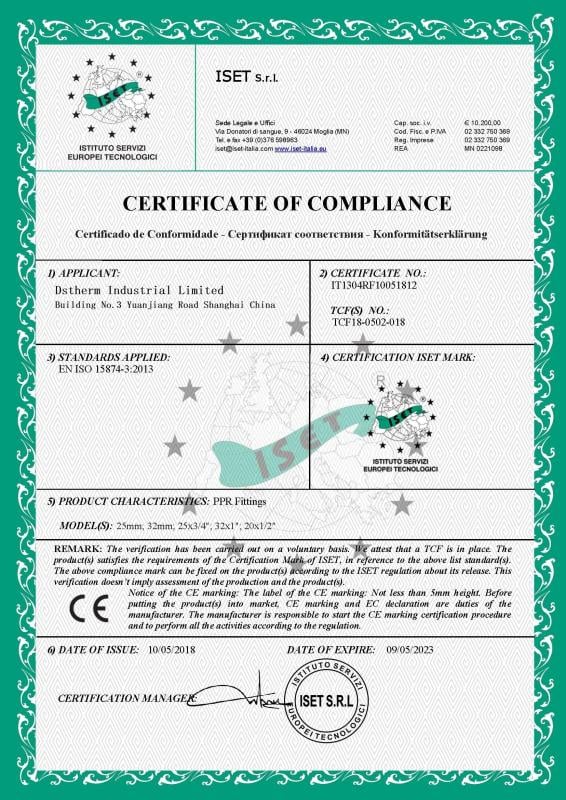

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Anti Scaling PPR Flange Core Heat Resistant 20 - 160mm Convenient Installation

PPR Pipe Fittings PPR Flange Core ISO9001 DIN8077/8078 Colour OEM size 40-160mm

PPR fitting manufactured from Polypropylene Random Copolymer raw material. The most important feature of PPR that distinguishes it from the others is that it could also be used in hot water systems besides being used in sanitary networks.

PP-R fitting is light, anti corrosive, anti-scaling and durable as ordinary plastic pipes and also has following main features:

1. Non-toxic and hygienic. Raw materials for PP-R fitting only contain carbon and hydrogen elements, and no harmful and toxic elements exist. Thus, PP-R fitting is hygienic and reliable. It is applicable not only to cold and hot water pipeline, but also to pure drinking water system.

2. Thermal insulating and energy saving. The thermal conductivity of the PP-R fitting is 0.21w/mk, which is only 1/200 of that of steels'.

3. Heat resistant. The vicat softening point of the PP-R fitting is 131.5 °C . The highest working temperature is up to 95 °C . It can meet the application requirements of hot water system in building water-supply and drainage standard.

4. Long service life. Under the condition that the working temperature is 70 °C and the working pressure is 1.OMP, the PP-R fittings' service life is up to over 50 years; the service life may be up to over 100 years under normal temperature.

5. Easy to install and reliable to connected. The PP-R has good weld ability, and the pipe and fittings may be connected through hot melting and electric melting. It is convenient to install and has reliable joints. The connection parts are tougher than the pipe itself.

6. There are bar code label on the tube, can easy track product information.

Descriptions of coupling

| Name | pp-r pipe fittings PPR Coupling PPR Socket |

| Color | green, white, gray, blue |

| Connection | socket fusion joint, electro fusion joint or transition joint |

| Material | polypropylene |

| Pressure Rating | 1.0Mpa,1.25MPa, 1.6MPa, 2.0MPa ,2.5MPa |

| Service life | 50 years |

| Size | 20mm-160mm |

Permissible Working Pressure And Longevity

| Working pressure(bar) | Temperature ℃ | Working year(H/Y) | |

| Cold water | 0 to10 transient | To 25 | 8760 |

| Hot water | 0 to10 transient | To 60 | 8710 |

| To 80 | 50 |

For Water Installations

Temperature |

Service life | Safety-factor=1.5 | |||

| SDR 11 | SDR 9 | SDR7.4 | SDR 6 | ||

| Nominal Pressere | |||||

| PN10 | PN12.5 | PN16 | PN20 | ||

| Permissible Working Pressure | |||||

| 20℃ | 1 | 15.0 | 18.9 | 23.8 | 30.0 |

| 10 | 13.7 | 17.3 | 21.7 | 27.2 | |

| 50 | 12.9 | 15.9 | 20.4 | 25.7 | |

| 40℃ | 1 | 10.8 | 13.6 | 17.1 | 21.2 |

| 10 | 9.2 | 12.4 | 16.0 | 20.2 | |

| 50 | 9.2 | 11.5 | 14.5 | 18.8 | |

|

50℃ |

1 | 9.2 | 10.8 | 14.5 | 18.3 |

| 10 | 8.2 | 10.5 | 13.1 | 16.5 | |

| 50 | 7.7 | 9.8 | 12.2 | 15.4 | |

| 60℃ | 1 | / | / | 12.2 | 15.4 |

| 10 | / | / | 11.0 | 13.8 | |

| 50 | / | / | 10.1 | 12.7 | |

| 75℃ | 1 | / | / | 9.9 | 12.3 |

| 10 | / | / | 7.5 | 9.3 | |

| 25 | / | / | 6.1 | 7.5 | |

SDR=Standard Dimension Ratio(diameter/wall thickness)

SDR=d/s(S=Pope series index from ISO 4065)

Feature

1. Sanitary & non-toxic;

2. Corrosion resistant & not scaling;

3. High temperature resistant & high pressure resistant;

4. Heat preservation & energy efficient;

5. Light weight;

6. Elegant appearance;

7. Convenient & reliable installation;

8. Long service life: over 50 years

Application of ppr pipe and fittings

1. The civil-use and industrial-use construction inner cold/warm water and water-giving systems;

2. Public sites, (such as schools, hospitals), gyms(such as swimming pools, playground);

3. Drinking water systems and food industry management system'

4. Garden and warm rooms irrigating systems;

5. Traditional heat-giving/ heat-absorbing systems;

6. Central air-conditioner system;

7. Chemical flowing transferring pipe system.

Our advantages

1). 15 Years' Experience in production

2). accept OEM Order

3). ISO9001 approved

4). We use All New raw material in products

5). Sufficient products with complete specifications for your choice