TPU Film 35 Khz Ultrasonic Sewing Machine With Rotary Horn

35Khz Ultrasonic sewing machine for TPU film sealing and cutting with rotary horn

Description

Ultrasonic welding is the process of converting electric current into electric energy through ultrasonic generator.The converted high-frequency electric energy then converted into the mechanical motion of the same frequency again through the transducer, and the mechanical movement is transmitted to the welding head through a set of horn device which can change the amplitude. The vibration energy received by the welding head is transferred to the joint of the work piece to be welded. In this area, the vibration energy is converted into heat energy by friction, and the plastic is melted. Ultrasonic can be used not only to weld hard thermoplastic plastics, but also to process fabrics and films. Heat energy comes from the reciprocating movement of a work piece on another surface with a certain displacement or amplitude under a certain pressure. Once the expected welding degree is reached, the vibration will stop, and at the same time, there will still be a certain pressure applied to the two work pieces to cool and solidify the just welded parts, thus forming a close combination.

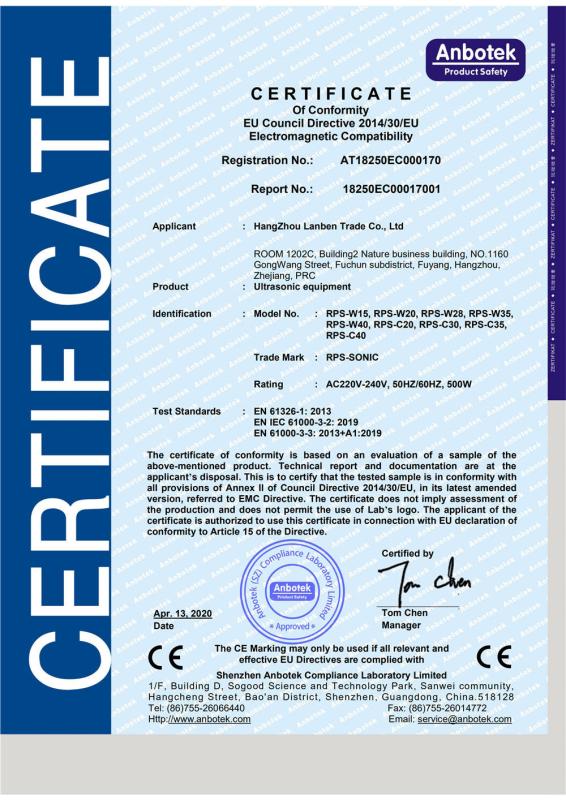

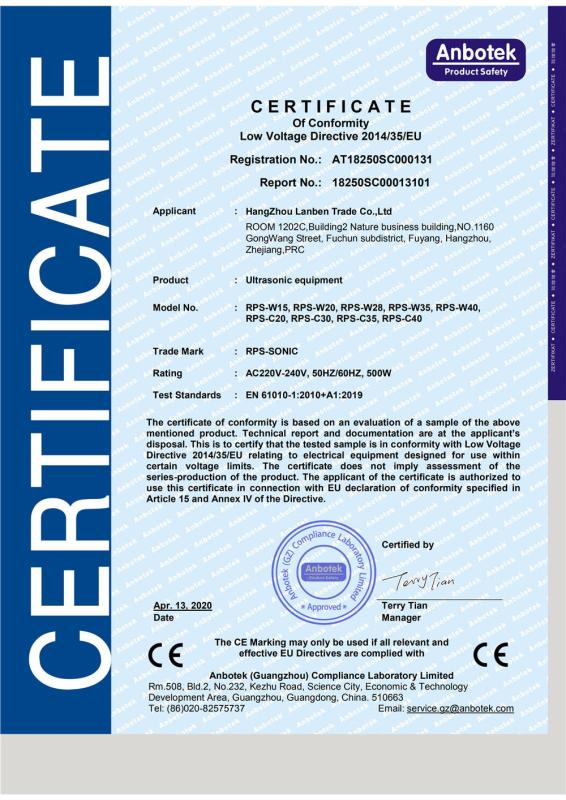

The RPS-SONIC SeamMaster provides rapid sealing, sewing, and trimming of synthetic fabrics without thread, glue, or other consumables. Although similar in appearance and operation to traditional sewing machines, the SeamMaster High Profile bonder has a higher clearance between the wheel and the horn, making it ideal for hand-guided applications with tight tolerances, or when working around curves. Ultrasonic bonding with the SeamMaster eliminates needle and thread breakage, thread color changeover and thread unraveling problems. And with production speeds up to 4 times faster than sewing, heat sealing and adhesive machines, the SeamMaster is highly cost-effective. RPS-SONIC’s SeamMaster is designed for specialized applications in the textile, apparel and engineered fabrics industries. A variety of interchangeable pattern rollers are available for slitting, embossing, and “stitching,” as well as custom pattern wheels designed by Sonobond engineers. The SeamMaster performs in one quick pass saving time, labor, and material. Seams bonded by RPS-SONIC’s Seam- Master are so perfectly fused and sealed that they can be used to help comply with OSHA’s regulations for barrier seams.

Features and Benefits

- Seams, trims, and seals without thread, glue, or other consumables

- Quick and efficient. Performs four times faster than conventional sewing machines and ten times faster than adhesive methods

- Larger wheel and high clearance above the bench allows for increased access for hand-guided operations

- Available as modular units for integration into production lines

- Virtually eliminates fraying or unraveling of bonded edges and seams

- Features a wide selection of inter- changeable roller patterns for seaming, hemming, embossing, and printing

- Requires minimal training to operate

- Combines several labor-intensive operations into one pass– saving time and money

- Helps meet OSHA regulations for barrier seams in medical apparel

- Exclusive SoftSeam™ process produces seams that are soft and smooth against the skin.

parameters:

| Output power : 600W |

| Power Input : 200V/50Hz |

|

Output frequency : 35KHz |

| Working temperature : -10-28C |

| Working speed : 0-8m/min |

| Equipped pattern mould : 0-100 mm |

| Size of machine ( L * W * H ) :1300 * 600* 1260 mm |

| Weight of machine : 150 Kg |