SEED TECHNOLOGIES CORP., LTD.

- Annual Revenue 30000000-40000000 USD

- Employees 450~600

- Year Established 2006

- Manufacturer, Exporter

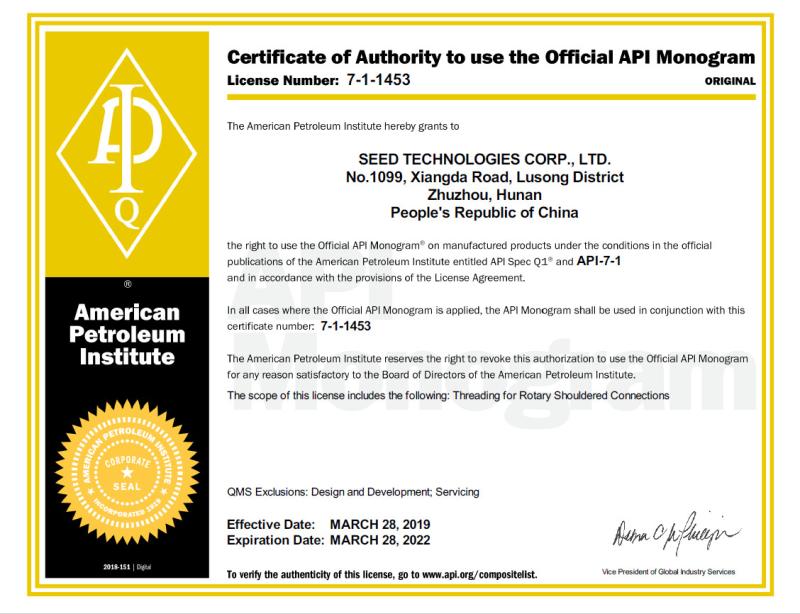

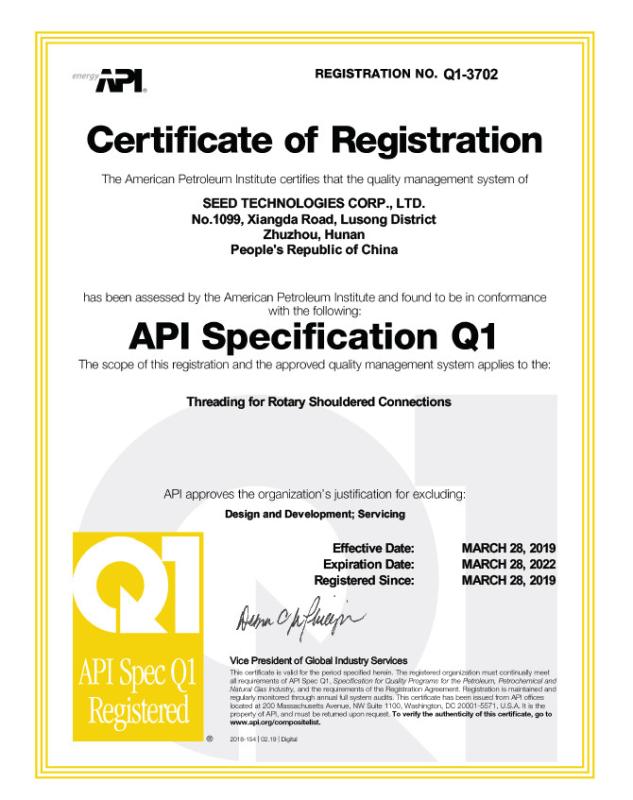

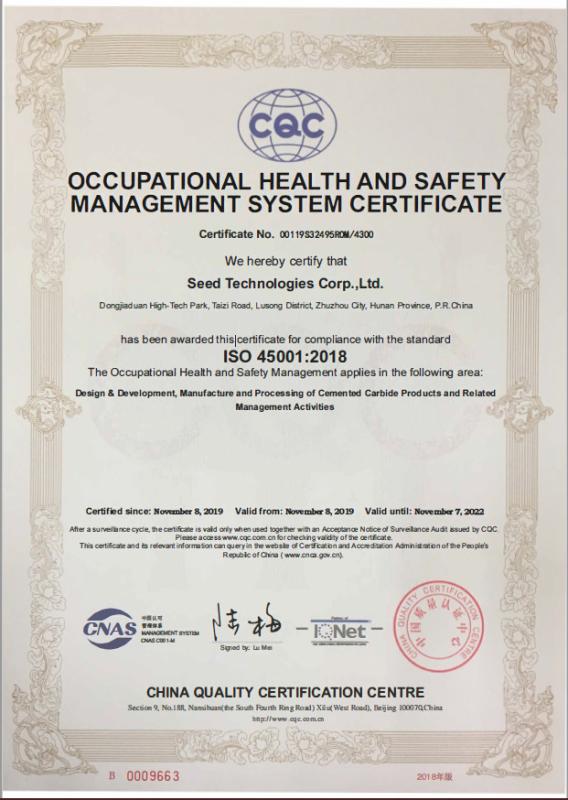

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

High Wear Resistance Tungsten Carbide Spray Nozzle For PDC Drilling Bit

High Wear Resistance Tungsten Carbide Spray Nozzle For Pdc Drilling Bit

Tungsten carbide nozzle is mainly used in chemical industry, food, machinery, metallurgy, architecture and other industries for pulverizing, derusting, cleaning, atomization, etc. Aseeder tungsten carbide nozzles are mainly for Oil Drilling Tools.

Features:

Aseeder Cemented tungsten carbide spary nozzle of oil field drill bit parts have a variety of specifications, processed and made with high quality raw material. It has the characteristics of high temperature resistance, corrosion resistance, abrasion resistance, high precision and so on.

Benefit

-

High efficiency for cooling, cleaning and cuttings evacuation, extend the drilling bit lift.

-

When tightening nozzle reduced pop-up force.

Recommended tungsten carbide grade list

| Grade | Co (Wt %) |

Density (g/cm3) |

Hardness (HRA) | TRS (≥N/mm²) |

| ZY11-C | 9.0-11.0 | 14.33-14.53 | 88.6-90.2 | 2800 |

| ZY15-C | 15.5-16.0 | 13.84-14.04 | 85.6-87.2 | 2800 |

| ZY15X | 14.7-15.3 | 13.85-14.15 | ≥89 | 3000 |

| ZY20 | 18.7-19.1 | 13.55-13.75 | ≥83.8 | 2800 |

| ZY06X | 5.5-6.5 | 14.80-15.05 | 91.5-93.5 | 2800 |

| ZY08 | 7.5-8.5 | 14.65-14.85 | ≥89.5 | 2500 |

| ZY09 | 8.5-9.5 | 14.50-14.70 | ≥89 | 2800 |

| ZY10X | 9.5-10.5 | 14.30-14.60 | 90.5-92.5 | 3000 |

Advantage::

- High stability, long lifespan circle.

- Customized as your requirements.

- Approved factory for oil and natural gas industry TOP10 customers.

- With ASP9100 certificate , API certificate, ISO9001:2015

- With a Special Thread Processing Workshop

Package :

Each unit will be packed into a plastic cylinder with foam, then put on carton box.

Major Product Lines

· Wear resistant carbide components via powder metallurgy technique

· Hardfacing (oxy-acetylene spray, PTA, HVOF, etc.) and surface enhancement (phosphating, boronizing, etc.)

· High-precision machining of metals (S.Steel, carbon steel, Inconel 718, etc.)

· Additive manufacture

The products and technologies from Seed (Aseeder) have been widely applied in the fields of oil & gas, chemical engineering, subsea, nuclear power and aerospace industries. Mainly used in harsh operating conditions include severe abrasion, erosion, corrosion, high temperature, high pressure and strong impact. Our major clients are Fortune 500 companies. Seed is the leading export enterprise in China of wear-resistant cemented carbide products and the related high-precision machining techniques.