Chongqing PurePath Green Technology Co.,LTD.

- Annual Revenue 100000000-20000000 USD

- Employees 50~100

- Year Established 2011

- Manufacturer, Exporter, Trading Company, Seller

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Wipe Film Evaporator Distillation Base Oil Refining Machine For Decolorization

Wipe Film Evaporator Distillation Base Oil Refining Machine For Decolorization

Product Description of WFE Base Oil Solvent Extraction Plant

Solvent extraction function as removal of majority of the aromatics and undesirable components of oil distillates by liquid extraction. For those waste oil without solid particle, variety of recycled or crude base oil, vacuum side streams, acid-refined oil, black diesel oil, waste hydraulic oil, waste transformer oil and waste mineral oil are able to be refined to new oil in water color and outstanding performance. Particularly in application of base oil, the refined base oil can meet or approach to the API II standard in parameter of viscosity, viscosity index, acid value, carbon residue, demulsification value, pour point, saturated hydrocarbon, similar to hydrofinishing base oil.

Highlights of WFE Base Oil Solvent Extraction Plant

- Various feeds: Variety of recycled base oil, vacuum side streams, acid-refined oil, black/red diesel oil, waste hydraulic oil, waste transformer oil and other kinds of waste mineral oil.

- Multistage centrifugal extractors are able to refine various feeds with different viscosity stably and efficiently.

- Free from secondary pollution for environment: no pollutant generated by solvent extraction.

- Low labor cost: Automation and continuous operation under Siemens PLC/SCADA control.

- Maximum utilization of solvent by thin film evaporator or wiped film evaporator solvent stripping process from polished oil.

- Much purer recovery solvent can be regenerated by high-efficiency solvent regeneration fractional distillation tower

- Less than 0.5 ASTM color scale polished oil approaching water color.

- Low cost in solvent (less than $12 USD to refine per ton of waste oil)

Performances of Polished oil from WFE Base Oil Solvent Extraction Plant

| Item | Unit | Method | Technical data after polishing | ||||||

| LBO | HBO | ||||||||

| Appearance | / | Visual Inspection | Bright & Clear | Bright & Clear | |||||

| ASTM Color | / | ASTM D1500 | <0.5 | 0.5 | |||||

| Kinematic viscosity@40℃ | mm2/s | ASTM D445-15a | 16~32.5 | 28~98.5 | |||||

| Viscosity index | / | ASTM D2270-04 | >120 | >125 | |||||

| Flash point(COC) | ℃ | ASTM D92-05 | >200 | >230 | |||||

| Poure point | ℃ | ASTM D97-11 | -12 | -9 | |||||

| TAN | mgKOH/g | ASTM D664 | <0.01 | <0.01 | |||||

| Sulfur content | %wt | ASTM D4294 | <0.010 | <0.010 | |||||

| Carbon Residue | %wt | ASTM D189 | <0.01 | <0.01 | |||||

| Saturated hydrocarbon | %wt | ASTM D2007 | 90~95% | 90~95% | |||||

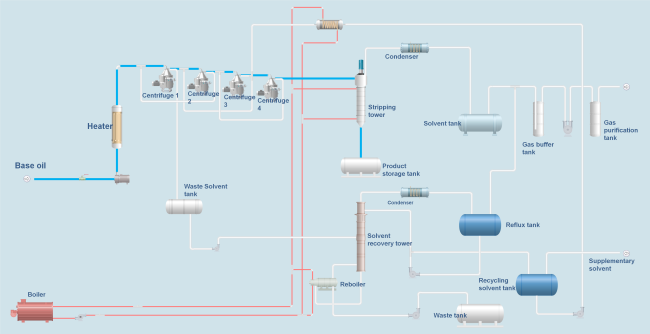

Technical Flow Chart of WFE Base Oil Solvent Extraction Plant

- Multiple stages centrifuge solvent extractor finishing times liquid-liquid extraction and separation with input base oil. Capture and separate the the aromatics and undesirable components.

- Used solvent will be sent to fractional distillation tower for recycling. Recovery rate is as higher as 99.9%.

- Extracted base oil makes its way to residual solvent stripping tower for further polishing.

- Gas generated during whole process will be collected and discharge after gas purification system.

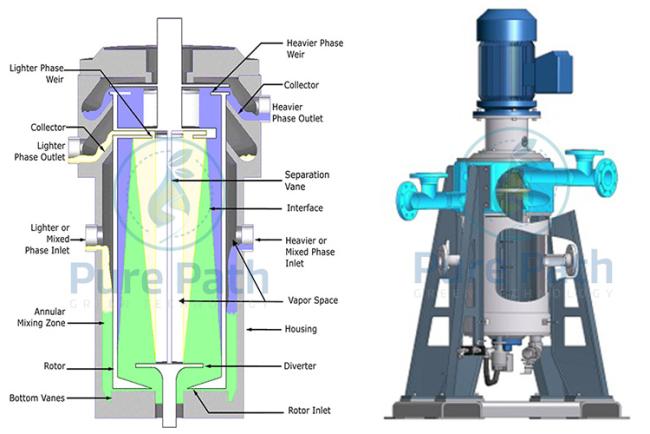

Efficient Centrifugal Extractor of WFE Base Oil Solvent Extraction Plant

PPGT-SE designes with many stanges centrifugal extractors, each centrifugal extractor represents once liquid-liquid extraction and separation. As higher as 2000mL/min immiscible solutions extraction and separaion, the new advanced centrifuge extraction machine optimal alternative traditional refining method or low efficient ones. The input and output rate is precisely calculated with Apsen/Pro II processing simulation by engineers from National Design Institute to ensure the oil and solvent reaction and separation well.

Factory Show

Customer Visiting

Successful Project Show

FAQ

1, What‘s the main purpose of PPGT-SE?

It's mainly used to upgrade base oil from vacuum distillation which is without good performance could be improved to water color, increase the viscosity and viscosity index, reduce the acid value and carbon residue; aromatics could be stripped to increase the content of saturated hydrocarbon above 90% to ensure the API group II standard base oil product.

2, Could we use PPGT-SE to others oil refining?

It could also be used for improving all kinds of mineral oil like used transformer oil, hydraulic oil, turbine oil, gear oil, all vacuum side streams, traditional distillation recycled red base oil, acid and alkali treatment base oil, TEPA and clay treated base oil.

Welcome to contact us for more details (+86 15213363289 WhatsApp / WeChat 24-H service)