CEBE GROUP HK CO.,LTD

- Annual Revenue 20 million-30 million USD

- Employees 10~50

- Year Established 2013

- Manufacturer, Distributor/Wholesaler, Agent, Exporter, Trading Company, Seller

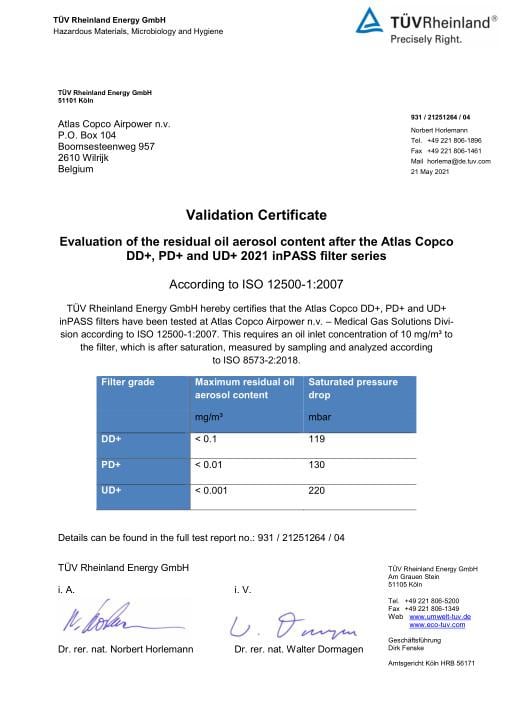

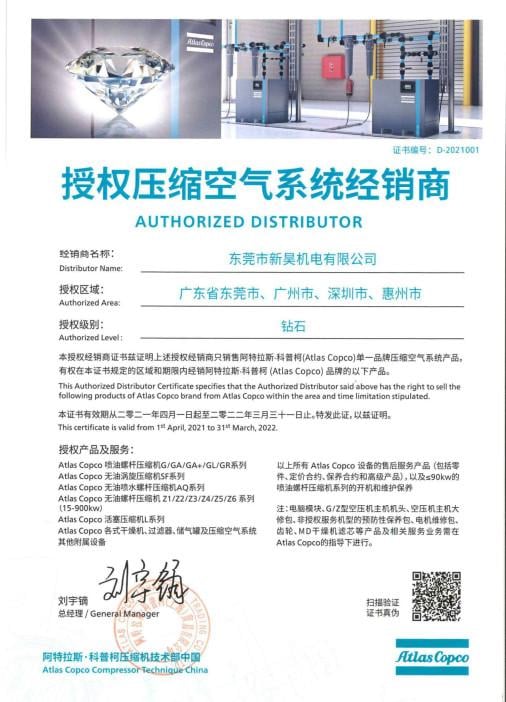

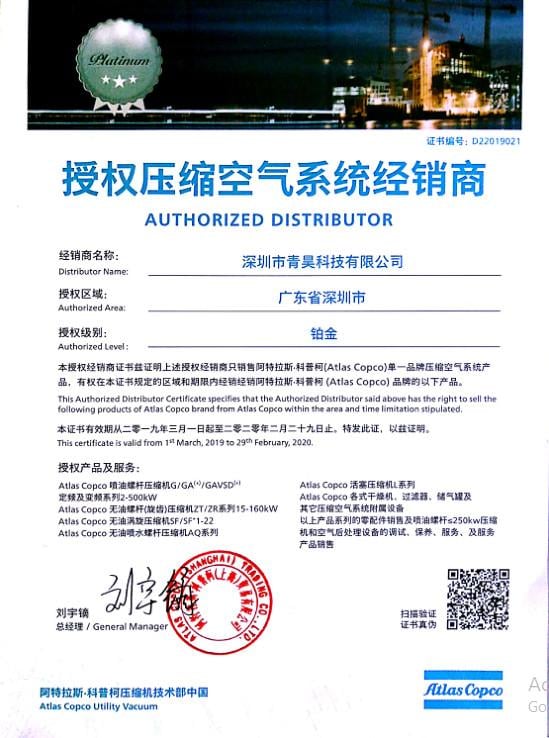

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

GA160- GA 250+ Atlas Copco Compressor 250kW 14 Bar 10 Bar Type Low Noise Level

GA160-250+50Hz Air Compressor

HIGHEST RELIABILITY, LOWEST OPERATING COSTS

The shortest route to maximize your profitability is to minimize your operational cost. As energy consumption is the major factor (up to 70%) of a compressor’s lifecycle cost, the Atlas Copco GA 160+-250 compressors are designed to help you achieve significant savings. The compressors provide high-quality compressed air to meet your requirements even in the most demanding applications.

High-efficiency motor

• TEFC IP55 motor (Class Finsulation B rise) protects against dust and chemicals.

• Continuous operation in ambient temperatures upto 46°C/115°F).

State-of-the-art screw element

• Patented asymmetric rotor profile and meticulous selection of bearings.

• Low wear and tear leads to increased reliability.

• Proven reliability with thousands of installations throughout the world.

Cooling module

• Separated oil and aftercoolers for highest efficiency.

• Axial cooling fans driven by separate TEFC electric motors(IP55 protection).

• Low noise level.

Gear-driven transmission

• Maintenance-free; totally enclosed and protected against dirt and dust.

• Optimal working range of the screw element.

• Bowex coupling to absorb the trust load and increase the reliability.

Service-friendly

• Selection of long lifetime consumables.

• Easy and safe access to all service parts.• Unique sliding system to access the oil coolers.

Optimized loading/unloading valve

• Ensures constant optimized pressure in the system,resulting in significant energy savings.

• Simple, maintenance-free set-up with few moving parts for highest reliability.

• Accurate control through solenoid valve.

SPECIFICATIONS

| TYPE | Working pressure | Capacity FAD (1) |

Installed |

Noise level (2) | Weight | ||||

| Standard | Standard | Standard | |||||||

| bar(e) | psig | l/s | m³/min | cfm | kW | dB(A) | kg | lb | |

|

GA 160+ - 5.5 bar |

5.5 | 80 | 621 | 37.2 | 1316 | 160 | 78 | 4793 | 10567 |

| GA 160+ - 7.5 bar | 7.5 | 109 | 538 | 32.2 | 1140 | 4648 | 10247 | ||

| GA 160+ - 8.5 bar | 8.5 | 123 | 498 | 29.8 | 1055 | 4648 | 10247 | ||

| GA 160+ - 10 bar | 10 | 145 | 448 | 26.9 | 949 | 4648 | 10247 | ||

| GA 200 - 5.5 bar | 5.5 | 80 | 748 | 44.8 | 1585 | 200 | 78 | 4913 | 10831 |

| GA 200 - 7.5 bar | 7.5 | 109 | 674 | 40.4 | 1428 | 4913 | 10831 | ||

| GA 200 - 8.5 bar | 8.5 | 123 | 632 | 37.9 | 1339 | 4768 | 10512 | ||

| GA 200 - 10 bar | 10 | 145 | 572 | 34.3 | 1212 | 4768 | 10512 | ||

| GA 200 - 14 bar | 14 | 203 | 440 | 26.4 | 932 | 4768 | 10512 | ||

| GA 220 - 5.5 bar | 5.5 | 80 | 837 | 50.2 | 1773 | 220 | 78 | 5099 | 11241 |

| GA 220 - 7.5 bar | 7.5 | 109 | 744 | 44.7 | 1576 | 5099 | 11241 | ||

| GA 220 - 8.5 bar | 8.5 | 123 | 671 | 40.2 | 1421 | 5099 | 11241 | ||

| GA 220 - 10 bar | 10 | 145 | 612 | 36.7 | 1296 | 4954 | 10922 | ||

| GA 220 - 14 bar | 14 | 203 | 492 | 29.6 | 1042 | 5954 | 10922 | ||

| GA 250+ - 5.5 bar | 5.5 | 80 | 923 | 55.4 | 1956 | 250 | 78 | 5099 | 11241 |

| GA 250+ - 7.5 bar | 7.5 | 109 | 833 | 50.0 | 1765 | 5099 | 11241 | ||

| GA 220+ - 8.5 bar | 8.5 | 123 | 773 | 46.4 | 1638 | 5099 | 11241 | ||

| GA 250+ - 10 bar | 10 | 145 | 709 | 42.5 | 1503 | 4954 | 10922 | ||

| GA 250+ - 14 bar | 14 | 203 | 575 | 34.5 | 1219 | 4954 | 10922 | ||