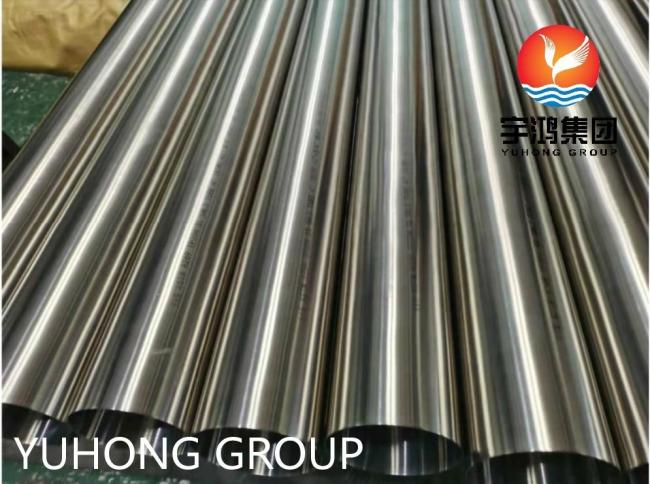

ASME SA269 TP304 304L 316 316L 321 Cold Drawn Stainless Steel Seamless Tubing Precision Bright Pipe

ASME SA269 TP304 304L 316 316L 321 Cold Drawn Stainless Steel Seamless Tubing Precision Bright Pipe

Yuhong Special Steel has been engaged in the operation of seamless welded pipes and pipes of austenitic stainless steel, nickel alloy steel (Hastelloy, Monel, Inconel, Inconel)

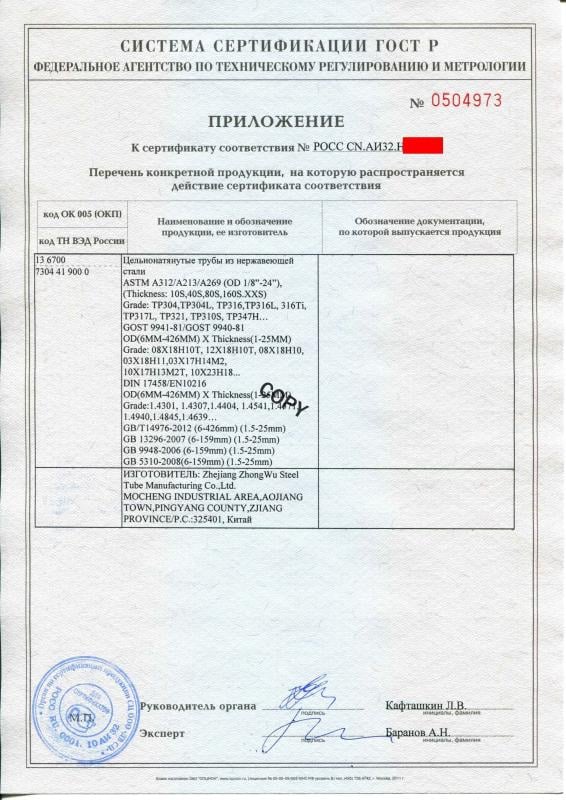

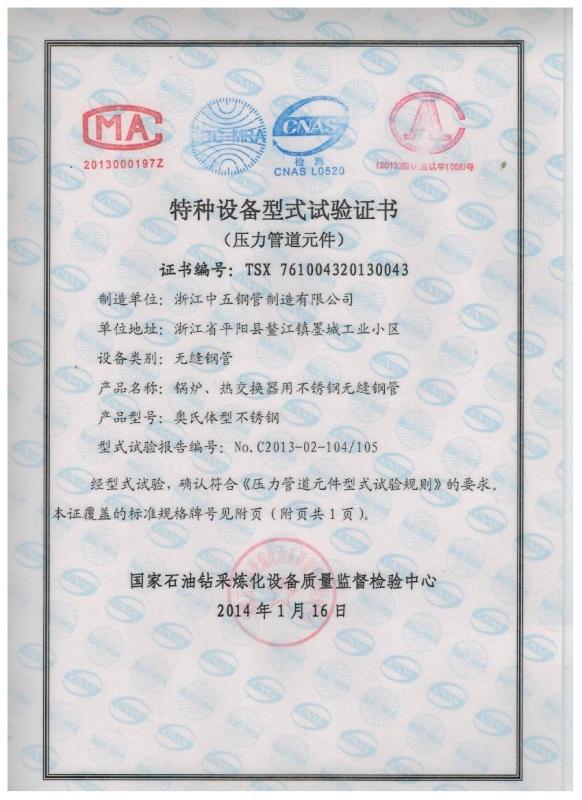

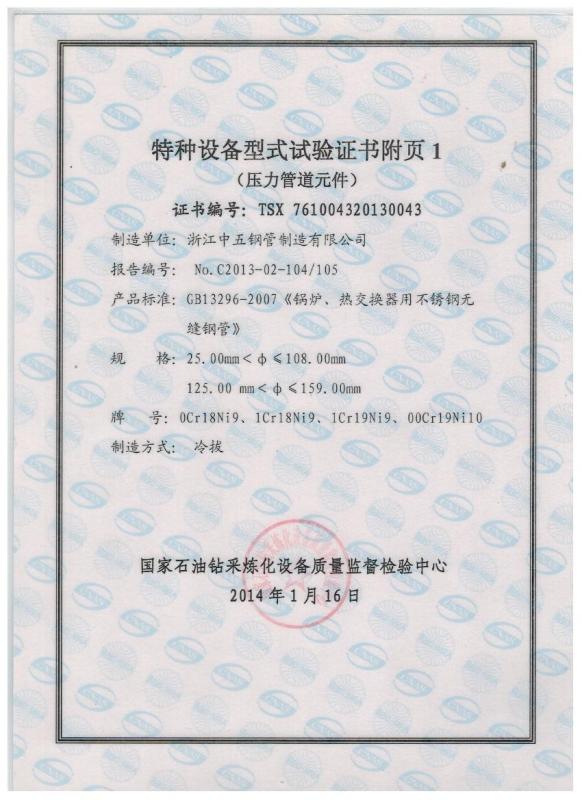

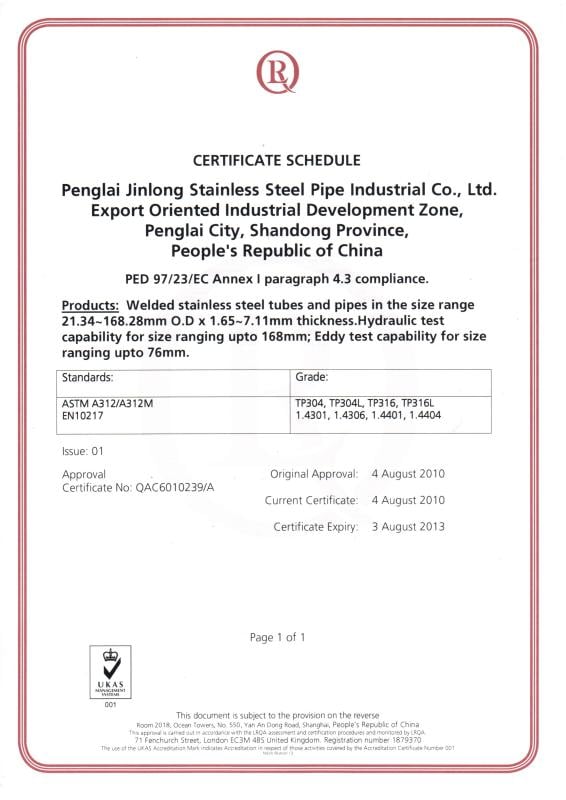

for more than 25 years, and annual sales of more than 80,000 tons of steel pipes and pipelines . pipeline. Our customers have covered more than 45 countries including Russia,

the United States, Canada, the United Kingdom, Germany, Italy, Chile, Colombia, Saudi Arabia, South Korea, Singapore, Australia, Poland and France.

Standard Specification:

ASTM A269/A269M: Standard Specification for General Seamless and Welded Austenitic Stainless Steel Pipe

ASTM A312 / A312M-12: Standard Specification for Seamless, Welded, and Re-cold Worked Austenitic Stainless Steel Pipe

ASTM A511 / A511M-12: Standard Specification for Seamless Stainless Steel Mechanical Pipe

ASTM A789/A789M-10a: Standard Specification for General Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASTM A790/A790M-11: Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

DIN 17456-2010: Universal seamless round stainless steel pipe.

DIN 17458-2010: Seamless round austenitic stainless steel tube

EN10216-5 CT 1/2: Stainless steel seamless pipes and tubes

GOST 9941-81: Seamless cold-worked and warm-worked tubes made of corrosion-resistant steel.

Other standards such as BS and JIS can be supplied

Material Grade:

| American Standard |

Austenitic Steel: TP304, TP304L, TP304H, TP304N, TP310S, TP316, TP316L, TP316Ti, TP316H, TP317, TP317L, TP321, TP321H, TP347, TP347H, 904L… Duplex Steel : S31803, S32101, S32205, S32304, S32750, S32760 Others: TP405, TP409, TP410, TP430, TP439,... |

| Europen Standard | 1.4162, 1.4301, 1.4307,1.4362, 1.4401, 1.4404, 1.4410, 1.4438, 1.4462, 1.4501, 1.4539, 1.4541, 1.4550, 1.4571, 1.4841, 1.4845,1.4878, 1.4948, |

| Russia Standard | 08Х17Т, 08Х13, 12Х13, 12Х17, 15Х25Т, 04Х18Н10, 08Х20Н14С2, 08Х18Н12Б, 10Х17Н13М2Т, 10Х23Н18, 08Х18Н10, 08Х18Н10Т, 08Х18Н12Т, 08Х17Н15М3Т, 12Х18Н10Т, 12Х18Н12Т, 12Х18Н9, 17Х18Н9, 08Х22Н6Т, 06ХН28МДТ |

Size Range:

| Production | Outside Diameter | Wall Thickness |

| Seamless Pipe | 6.00mm-830mm | 0.5mm-48mm |

Specifications: ASTM A/ASME SA213/A249/A269/A312/A358 Pipes and Tubes Sizes (Seamless): 1/2" NB - 16" NB

Pipes and Tubes Sizes (ERW): 1/2" NB - 24" NB

Pipes and Tubes Sizes (EFW): 6" NB - 100" NB

Pipes and Tubes Wall Thickness available: Schedule 5S - Schedule XXS (heavier on request)

Pipe and Tubes Other Materials Testing: NACE MR0175, H2 SERVICE, OXYGEN SERVICE, CRYO SERVICE, etc.

Dimensions: All Pipe is manufactured and inspected/tested to the relevant standards including ASTM, ASME and API etc.

A269 TP304 Stainless Steel Seamless Tube Chemical Composition

| SS | 304 | 304N | 304LN |

| Ni | 8 – 11 | 8 – 11 | 8 – 11 |

| Fe | Balance | ||

| Cr | 18 – 20 | 18 – 20 | 18 – 20 |

| C | 0.08 max | 0.08 max | 0.035 max |

| Si | 0.75 max | 0.75 max | 0.75 max |

| Mn | 2 max | 2 max | 2 max |

| P | 0.040 max | 0.040 max | 0.040 max |

| S | 0.030 max | 0.030 max | 0.030 max |

| N | 0.10 – 0.16 | 0.10 – 0.16 | |

A269 TP304 Stainless Steel Seamless Tube Mechanical Properties

| Density | 8.0 g/cm3 |

| Melting Point | 1400 °C (2550 °F) |

| Tensile Strength | Psi – 75000 , MPa – 515 |

| Yield Strength (0.2%Offset) | Psi – 30000 , MPa – 205 |

| Elongation | 35% |

A269 TP304 Stainless Steel Seamless Tube Physical Properties

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 304/H | 8000 | 193 | 17.2 | 17.8 | 18.4 | 16.2 | 21.5 | 500 | 720 |

Final Finishing:

Solution Annealed & Pickled

Application:

- Food processing equipment, especially beer brewing, milk processing and wine making.

- Kitchen benches, sinks, sinks, equipment and appliances

- Building paneling, railings and decoration

- Chemical containers, including for transportation

- Heat exchanger

- Woven or welded screens for mining, quarrying and water filtration

- Threaded fasteners

- Spring

- Other