Agricultural Waste Organic Fertilizer Production Line 8tph Fermented

Cow Manure Animal Waste Poultry Manure Organic Fertilizer Production Line

Introduce:

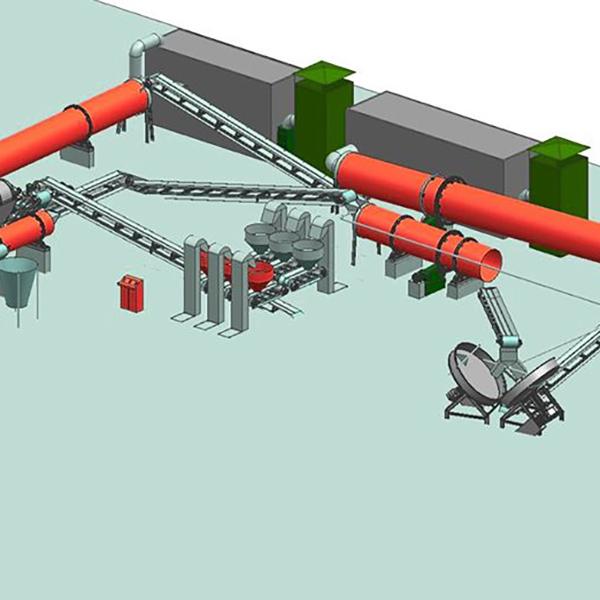

The organic fertilizer production line is commonly used to process different fermented organic substance into bio-organic fertilizer. It adopts one-step molding technology. Animal manure and agricultural waste are recycled as the main raw materials, thus manure or dung waste is not only creating economic benefits for the enterprise, but also making a great contribution to environmental projects for mankind.

After safety disposal and fermentation, these materials are made into organic fertilizer. Thus, organic fertilizer containing a variety of organic acids, peptides, and rich nutrients including nitrogen, phosphorus and potassium. Not only provide comprehensive nutrition for crops, also with long fertilizer effect, which can Increase and update the soil organic matter and promote microbial breeding, improve soil physical and chemical properties and biological activity.

Organic fertilizer raw materials:

1. Agricultural waste: such as straw, soybean meal, cotton meal, mushroom residue, biogas residue, fungus residue, lignin residue, etc.

2. Livestock and poultry manure: such as chicken manure, cattle, sheep and horse manure, rabbit manure;

3. Industrial waste: such as distiller's grains, vinegar grains, cassava residue, sugar residue, furfural residue, etc.;

4. Domestic waste: such as food waste, etc.;

5. Urban sludge: such as river sludge, sewage sludge, etc. China's organic fertilizer raw materials classification: mushroom residue, kelp residue, phosphorus citric acid residue, cassava residue, sugar aldehyde residue, amino acid humic acid, oil residue, shell powder , etc., and peanut shell powder.

6. The development and utilization of biogas slurry and residue is one of the important contents of biogas promotion. According to many years of experiments, the utilization of biogas slurry and residue has many functions such as improving soil, preventing pests and diseases, and increasing yield.

Advantages of powder production line:

1. Fit for new starter in fertilizer making field

2. Small investment, high return

3. The organic matter content is high, which has a significant effect of improving soil and fertilizing;

4. The nutrients contained are comprehensive, but the content is low, and the fat is small;

5. The fertilizer supply time is long, the fertilizer effect is slow and lasting;

6. It can fully integrate with the soil to form an organic complex, so the loss is small and the utilization rate is high.