CEBE GROUP HK CO.,LTD

- Annual Revenue 20 million-30 million USD

- Employees 10~50

- Year Established 2013

- Manufacturer, Distributor/Wholesaler, Agent, Exporter, Trading Company, Seller

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

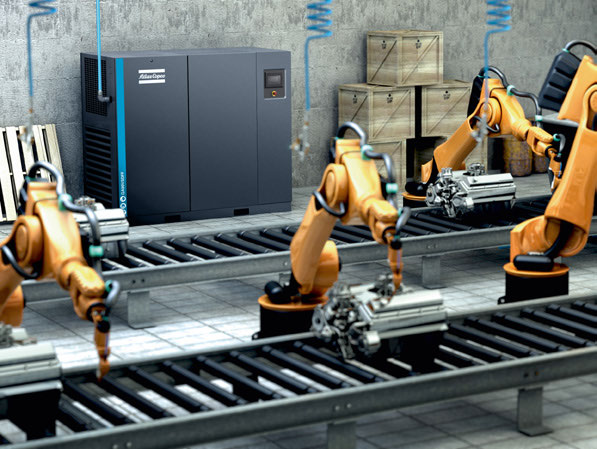

90kw GA 90 Atlas Copco GA Series 60Hz Aluminum Alloy Material

GA 90 60Hz Air Compressor

SPECIFICATIONS

| COMPRESSOR TYPE |

Pressure variant | Max. working pressure WorkPlace |

Capacity FAD* | Installed motor power | Noise level** | Weight WorkPlace | Weight WorkPlace Full Feature |

||||||

| bar(e) | psig | l/s | m³/min | cfm | kW | hp | dB(A) | kg | lbs | kg | lbs | ||

| GA 90 | 100 | 7.4 | 100 | 285 | 17.4 | 604 | 90 | 125 | 74 | 1525 | 3355 | 1645 | 3619 |

| 125 | 9.1 | 125 | 261 | 15.7 | 553 | 90 | 125 | 74 | 1525 | 3355 | 1645 | 3619 | |

| 150 | 10.8 | 150 | 240 | 14.4 | 509 | 90 | 125 | 74 | 1525 | 3355 | 1645 | 3619 | |

| 175 | 12.5 | 175 | 224 | 13.4 | 475 | 90 | 125 | 74 | 1525 | 3355 | 1645 | 3619 |

|

Lowest lifecycle costs and peace of mind

• No extra installation costs.

• Saving floor space.

• Use of energy-efficient, environmentally friendly refrigerant R410A reduces operating costs and stands for zero ozone depletion.

• Heat exchanger cross-flow technology with low pressure drop,saving energy and costs.

• Zero waste of compressed air thanks to no-loss condensate drain.

• Advanced control functions ensure dry air under all circumstances and prevent freezing at low load.

• Pressure dew point of 3°C (100% relative humidity at 20°C).

1. Maintenance-free drive system

• 100% maintenance-free; totally enclosed and protected against dirt and dust.

• Suitable for harsh environments.

• High-efficiency drive arrangement; no coupling or slippage losses.

• Standard up to 46°C/115°F and for high ambient version 55°C/131°F.

2. IE3 Premium Efficiency electrical motors

• IP55, insulation Class F, B rise.

• Non-drive side bearing greased for life.

• Oil lubricated drive side bearings.

3. Robust spin-on oil filter

• High-efficiency, removing 300% smaller particles than a conventional filter.

• Integrated bypass valve with the oil filter.

4. Separate oversized oil cooler and aftercooler

• Low element outlet temperatures, ensuring long oil lifetime:• Removal of nearly 100% condensate by mechanical separator.

• No consumables.

• Eliminates possibility of thermal shocks in coolers.

5. Advanced control & monitoring via Elektronikon®

• Integrated smart algorithms reduce system pressure and energy consumption.

• Monitoring features include warning indications,maintenance scheduling and online visualization of machine’s condition.

6. Heavy-duty air intake filter

• Protects the compressor components by removing99.9% of dirt particles down to 3 microns.

• Differential inlet pressure for proactive maintenance while minimizing pressure drop.

7. Electronic no-loss water drain(optional)

• Ensures constant removal of condensate.

• Manual integrated bypass for effective condensate removal in case of power failure.

• Integrated with compressor’s Elektronikon® with warning/alarm features.

8. Radial fan

• Low noise level.

• High flows.

• Compact design.

9. Integrated highly efficient R410A dryer

• Excellence in air quality.

• 50% reduction in energy consumption compared to traditional dryers.

• Zero ozone depletion.

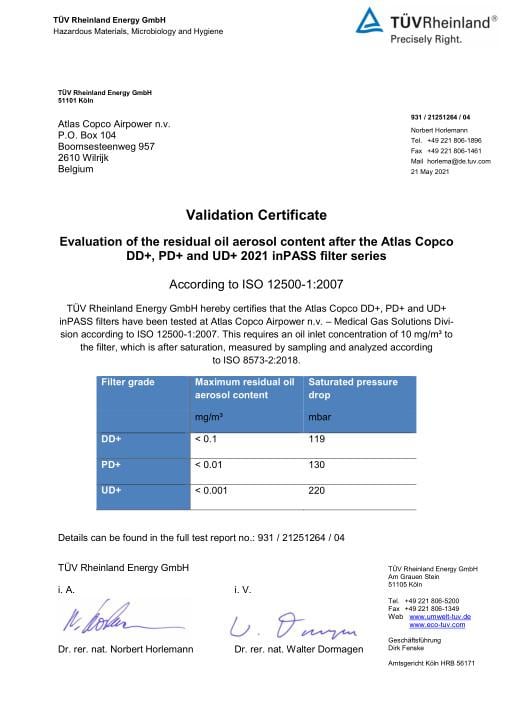

• Incorporates optional UD+ filter according to Class 1.4.2.

WorkPlace:

Compressed air at the point of use

With the industry-leading low noise operation and integration of air and condensate treatment equipment, the GA+ offers complete versatility for your production. The compressor’s integrated design allows it to be placed on the production floor, creating substantial energy savings for your business.