17000 Bottles Mineral Water Filling Machine for Mass Production

Briefs on Product

a. This type of carbonated beverage filling machine is for carbonated drink production line.

b. Heavy duty 304 stainless steel welded frame, 316 stainless steel hygienically processed filling nozzles and capping heads.small carbonated drink filling machine

c. Siemens PLC system along with Omron photoelectric sensor make this machine smart.

d. 7-inch touch screen tames this steel beast perfectly.

e. The capacity is around 17000 bottles per hour.(up to 18000bph)

f. The filling nozzle stroke is adjustable to the different volumes of bottle.(200ml-2500ml)

g. Faster and more effective product and bottle changeover reduces your product losses.

h. Hygienic design for easy resource-saving sanitizing.

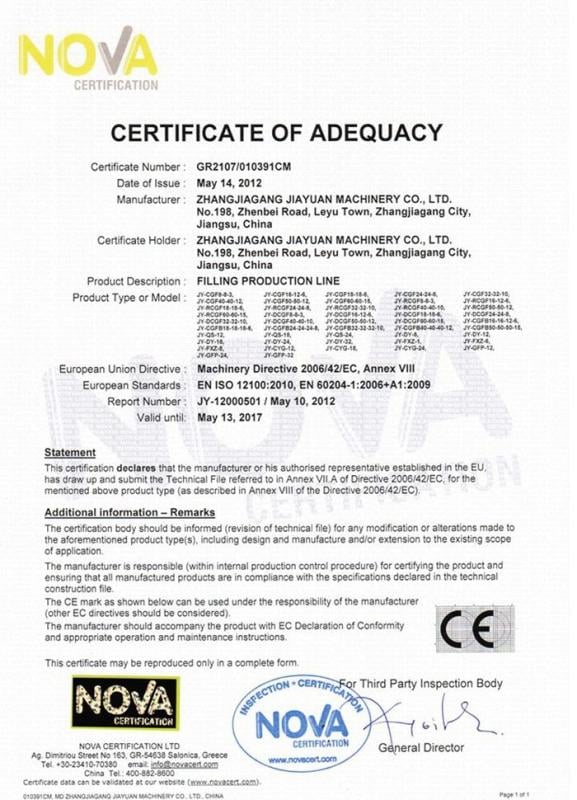

Having been proved by certificates like SGS, CE.

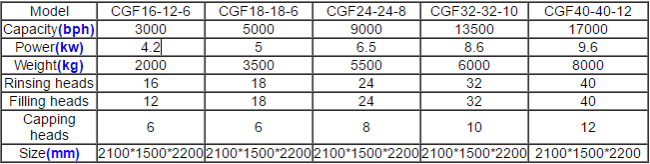

Products of CGF series

Detailed Images

|

a. Plier-like clutches could easily hook up bottle's neck without doing any damage. b. Neck-catching design makes it fit bottles with a large range of size. c. Made of stainless steel where durability comes from. |

|

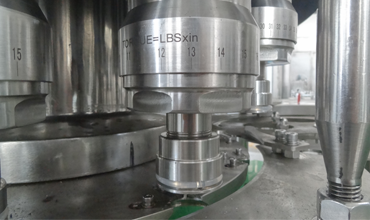

a. 316 stainless steel made filling nozzles, sanitarily reliable and durable. b. Nozzle stroke can be adjusted through a certain range, making the filler variably fit different bottle volumes(200ml-2500ml). c. Stabilizer contacting bottle's bulk down below is made of polymer materials. d. Enhanced by the photoelectric sensor, no bottle no fill. e. Bulged constituents make nozzle easy to clean. |

|

|

a. Made of stainless steel 316, ensuring durability. b. Caps are put onto the bottles by the cap sorter upstream c. Enhanced by the photoelectric sensor, no bottle no cap. d. Easily adjustable cap torque settings make it smooth to operate. e. Simple and easy-to-change parts facilitate the adjustment between different sizes of bottles and caps. |

Quality Assurance

Company Info

Company Information:

We locate in ZhangJiaGang, a small city near ShangHai. We have several certificates such as CE,SGS,etc. we have a batch of decent manufacturing facilities, professional staff, diligent and farsighted leadship. Our machines are widely sold domestically and abroad. We've been majoring in complete beverage production line, including pure/mineral water production line, non-carbonated drinks production line, carbonated drinks production line.

Packaging and Shipping

Our Service

1. If you are interested

a. Contact us for more detailed info, We are willing to answer your questions.

b. We highly recommend you come to our factory to check out the machine personally, You would be picked up and treated with a warm reception.

2. Customized service

a. We could design and build the machines according to your requirements(material, power, filling method, type of bottle, some certain modules, etc). Meanwhile, we could also give you professional suggestions.

b. We also offer turnkey project, help you design production-line layout and train skilled employees who are able to operate properly.

carbonated beverage filling machine

3. After-sales service

a. We set your shopping experience as our top priority, we will produce as exactly you require and let you get your machine as soon as possible.

b. Our engineers will arrive at your factory right after the machine's arrival. They will help install the machine and teach your employees how to operate properly.

c. We provide one year warranty with free spare components.