Anhui Jinjiuding Composites Co., Ltd.

- Annual Revenue 9 million-10 million USD

- Employees 50~70

- Year Established 1998

- Manufacturer, Distributor/Wholesaler, Exporter, Seller

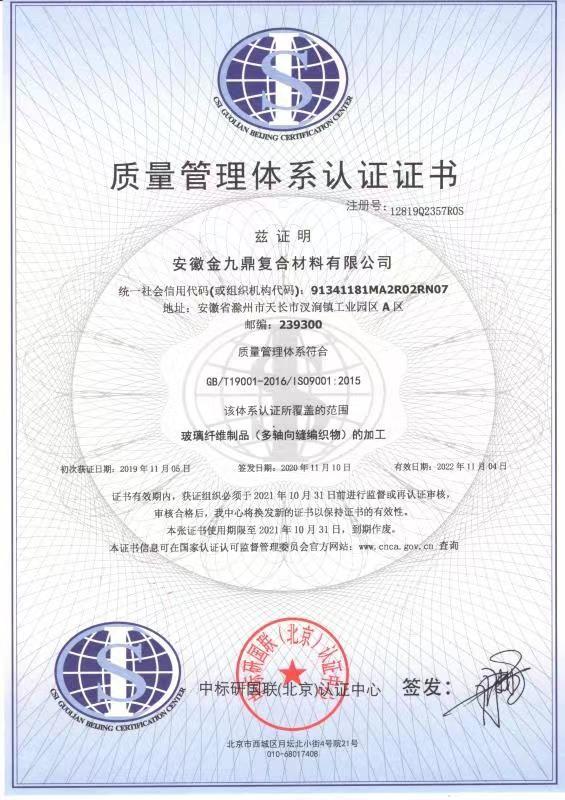

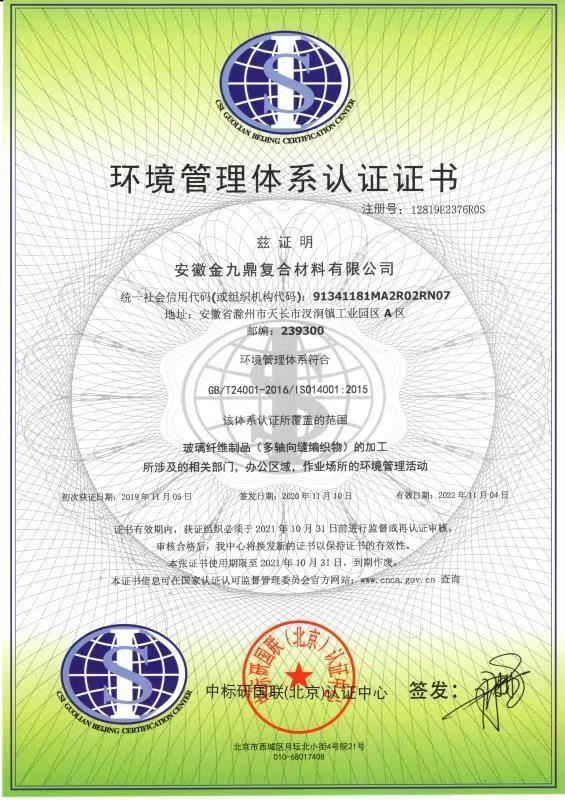

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Anti Corrosion Double Bias Fiberglass Cloth Roll 0.1mm To 3mm

Fiberglass biaxial fabric with high tensile strength comptatiable with all types of resin used in sports equipment

Introduction:

Fiberglass biaxial fabric is a cloth in which the roving is arranged in a two-way direction at 90º (transverse) and 0º (longitudinal), and then stitched with a coil structure. It can be stitched two-way layer yarn with chopped strand mat, polyester surface felt, fiberglass surface felt, carbon fiber surface felt, etc., processed into various types of composites fabric to obtain specific performance.

Specifications:

| Product NO. |

Overall Weight (g/m2) |

0°Roving (g/m2) |

90°Roving (g/m2) |

Chopped Roving (g/m2) |

Polyester Felt (g/m2) |

Width (mm) |

| ELT 450 | 450 | 250 | 200 | / | / | 150 - 2600 |

| ELT 600 | 600 | 336 | 264 | / | / | 150 - 2600 |

| ELT 800 | 800 | 420 | 380 | / | / | 150 - 2600 |

| ELTP 500 | 500 | 250 | 210 | / | 40 | 150 - 2600 |

| ELTM 600 | 600 | 250 | 200 | 150 | / | 150 - 2600 |

| ELTM 900 | 900 | 336 | 364 | 200 | / | 150 - 2600 |

| ELTM 1050 | 1050 | 336 | 414 | 300 | / | 150 - 2600 |

| ELTM 1200 | 1200 | 420 | 430 | 350 | / | 150 - 2600 |

| ELTMP 640 | 640 | 250 | 200 | 150 | 40 | 150 - 2600 |

Features:

● No binder content, good wet out of resin

● Provide mechanical strength of the product i multi direction

● Fiber straight arrangemet, max. usage of fiber strength

● Interspaces between the fibers are small, effectively improve the impact resistance of products

Application:

● Compatiable with reinforeced unsaturated polyester resin, vinlylester resin, epoxy resin, phenolic resin and polyurethane resin etc.

● Forming process includes vacuum infusion molding, pultrusion, hand lay-up, RTM etc.

● The typical end-use applications are FRP boat hull, wind power blade, sports equipment, pultruded profile and auto body etc.

Visit Website