Hermetic TFT Touch Screen Environmental Test Chambers 216L

Combined Climate Testing Chamber Temperature Humidity Vibration Composite Test Chamber Environmental Test Chambers

Product description

Three comprehensive test chamber can simulate the temperature and humidity environment, and with the vibration table, it can carry out the comprehensive reliability test of the three environmental factors of temperature and humidity vibration. It can be matched with the vertical shaking table or the horizontal sliding table of the shaking table.

Use

Three comprehensive vibration testing machine trial electronic, electrical products, automotive industry, military enterprises and its original devices and other materials in high temperature, low temperature, hot and humid, alternating hot and humid and vibration environment storage, transportation, so that the production of adaptability test. The three integrated temperature humidity test chamber is mainly used for the product in accordance with national standards or set requirements, the user in the low temperature, high temperature, damp and hot, alternating hot and humid, and vibration conditions, the characteristics of physics and other related product environmental simulation test, test, through testing, to judge the performance of the products, whether can still conform to the requirements of the book, For product design, improvement, appraisal and delivery inspection.

Features

1. Adopt non-reactive door handle, easier to operate;

2. It is made of constant temperature and humidity box and V series electromagnetic vibration test;

3. Vibration controller, sensor and power amplifier are imported from the United States;

4. Sine vibration (standard), random vibration (optional) and impact (optional) control;

5. It can be designed and manufactured to meet the requirements of low pressure;

6. The observation window is made of multi-layer hollow tempered glass, and the inner side is glued with a conductive film (the test process can be clearly observed);

7. Lead hole (left side of machine) can be connected to test power line or signal line (diameter: 50 mm);

8. Multiple security protection, safe and reliable grounding protection device, the power supply under voltage, over voltage, lack of phase, phase sequence error protection, temperature automatic protection, ultra high temperature heater short circuit/overload protection, refrigerator overpressure/overload protection, over-voltage protection, air blast cooling coil motor overload/overheating protection, control panel over-current protection, leakage protection.

Spec

| Model | Air-coled condenser | BTHV225-70A | BTHV512-70A | BTHV1000-70A |

| Water-cooled condenser | BTHV225-70W | BTHV512-70W | BTHV1000-70W | |

| Interior capacity(L) | 216 | 512 | 1000 | |

| Interior Dim(cm) |

Width | 60 | 80 | 100 |

| Height | 60 | 80 | 100 | |

| Depth | 60 | 80 | 100 | |

| Exterior Dim(mm) | Depends on the model | |||

| Performance parameter |

Temperature | ’-70℃~150℃ | ||

| Humidity range | 20%~98%RH | |||

| Temperature deviation | ±2℃ | |||

| Temperature fluctuation | ±0.5℃ | |||

| Relative Humidity fluctuation | ±5%RH(≤75%RH) ±3%RH(≤75%RH) | |||

| Heating rate | 1~15℃/min(optional) | |||

| Cooling rate | 1~15℃/min(optional) | |||

| Refrigeration system |

Refrigeration method | Mechanical double-stage refrigeration system | ||

| Compressor | Semi-Hermetic/Hermetic compressor | |||

| Cooling pattern | Air/Water-cooled condenser | |||

| Control system |

Controller | TFT touch screen | ||

| Language | Chinese or English | |||

Details

Our Services

During the whole business process, we offer Consultative Selling service.

1) Customer inquiry process:

Discussing testing requirements and technical details, suggested suitable products to customer to confirm. Then quote most suitable price according to customer requirements.

2) Specifications customize process:

Drawing related drawings to confirm with customer for customized requirements. Offer reference photos to show the products appearance. Then, confirm the final solution and confirm final price with customer.

3) Production and delivery process:

We will produce the machines according to confirmed PO requirements. Offering photos to show production process.

After finish production, offer photos to customer to confirm again with the machine. Then do own factory calibration or third party calibration(as customer requirements). Check and test all the details and then arrange packing.

Deliver the products in confirmed shipping time and inform customer.

4) Installation and after sale service:

Defines installing those products in the field and providing after-sales support.

NO.1 One machine multi-purpose

NO.2 Programming control

NO.3 Testing download

NO.4 High performance

NO.5 Custom production

PACKAGE&DELIVERY

1.Standard exported package: Internal anticollision protection, external export wooden box packaging.

2.Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3. Responsible for the damage during the shipping process, will change the damage part for you for free.

4.15-20days after confirming order,detail delivery date should be decided according to production season and order quantity.

ABOUT US

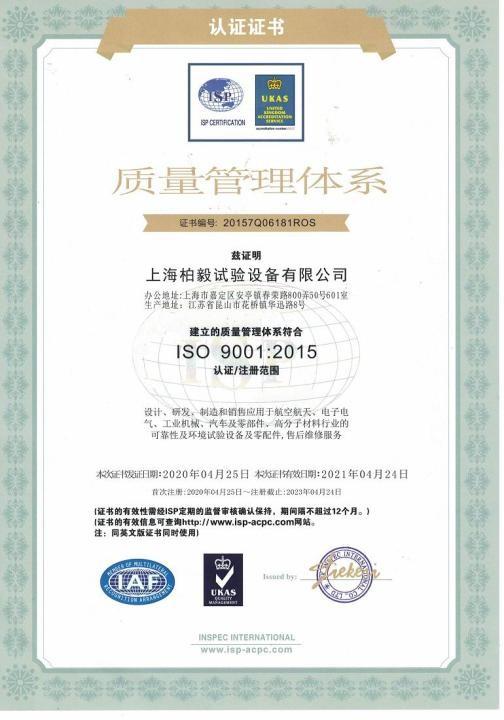

BOTO GROUP LTD.Is a professional manufacturer of environmental test equipment and test service. Our company was established in 1998,the plant covers 55,000 square meters and a construction area of 6,800 square meters, existing 160 workers and we can provide operation video for machines.

The policy the company adheres to:TODAY'S QUALITY IS THE MARKET FOR TOMORROW.

Our Team