Aromatherapy Toothpaste Box Packing Machine Cartoning 80boxes/Min

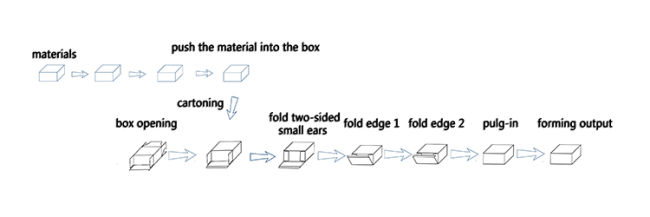

Horizontal automatic packing machine is a high-tech product integrating light, electricity, gas and machine.Suitable for automatic packing of various products.The working process is the transfer of goods;The carton is automatically propped open and transferred, and materials are automatically put into the carton.And the completion of both ends of the paper tongue packaging process.The shape of the machine is all made of high-quality stainless steel shell, and it is designed in strict accordance with the GMP standard in the pharmaceutical industry.In the transmission part, the overload protection function is designed and the emergency stop device is set up.The man-machine interface video screen is adopted in the control system to ensure the personal safety of the operator.

Technical Parameters

| Description | Automatic cartoning machine |

| Model | ZH-Series Cartoning machine |

| Speed | 50-80 boxes/min |

| Carton specification | Paper material 250-400g/m2 ( need flat surface) |

| Box size L*W*H(100-240)*(15-150)*(25-85)mm | |

| Power supply | 220V/380V,50HZ. Main motor 1.5kw |

| Dimension | 3600*1200*1700mm( L*W*H) |

| Weight | 1300kg |

| Air supply | ≥0.6Mpa |

| Air consumption | 20m3/H |

| Glue machine | China Jingtai(optional ) |

Features

1. The machine is equipped with glue spraying device, which adopts hot melt glue spraying and sealing box.

2. The front of the machine is equipped with a conveyor belt device for automatic feeding, which is can be connected to the production line for use.

3. It can automatically complete the packing work of automatic feeding, box opening, box entering, box sealing and output, etc., with compact and reasonable structure and simple operation and adjustment.

4. The machine adopts servo motor, touch screen and PLC programmable control system, which makes the man-machine interface display operation more clear and simple, with high degree of automation and more humanize.

5. The machine adopts photoelectric eye automatic detection and tracking system, no product will not suck the box, saving packaging materials to the greatest extent.

6. Large packaging range, convenient adjustment, and quick conversion between various specifications and sizes.

7. Changing specifications does not need to change the mold, only need to adjust to achieve.

8. When there is no product or the product supply is not in place, the machine runs idly without pushing the product. When the product resumes supply, it will automatically run, the product will automatically stop when it is not in place, and the main drive motor overload protection device is more safe and reliable.

9. The machine has product count and speed display function.

10. The machine can be used alone or in conjunction with other equipment to form a complete production line. It can realize linkage production with aluminum plastic packaging machine, pillow packaging machine, three-dimensional packaging machine, bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument, other production lines and other equipment.

Machine Details

Work Process

Product