Chongqing PurePath Green Technology Co.,LTD.

- Annual Revenue 100000000-20000000 USD

- Employees 50~100

- Year Established 2011

- Manufacturer, Exporter, Trading Company, Seller

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Scada Automatic Control Waste Engine Oil Distillation Plant To No Odor Diesel

Scada Automatic Control Waste Engine Oil Distillation Plant To No Odor Diesel

Product Description of Scada control waste engine oil distillation plant

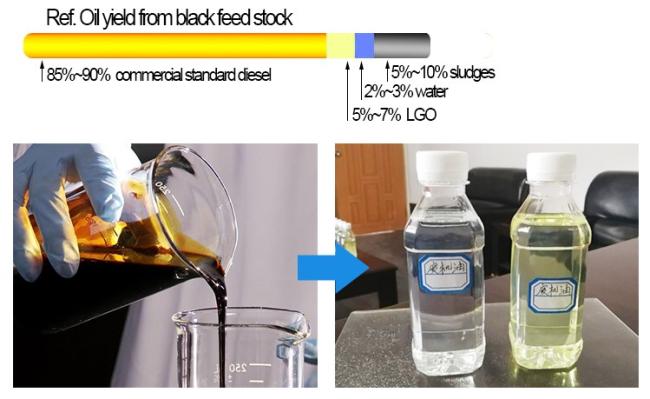

We are proud to present you with our PPGT-LP waste oil cracking distillation plant which is combined with dozens of our newest technologies to delivery you with the excellent quality of diesel oil out of different type of car engine and machinery engine or industrial waste oil, tire and plastic pyrolysis oil and sludge oils.

As the manufacturer, PurePath owns professional engineering team to provide constructively project proposal according to different waste oil feedstock or standard requirement of the final oil products. In order to get a more clear and purier distillates, genuine continuous fractional distillation and further PurePath exclusive desulfurization system are optional. Before the process of distillation begins, we also highlight the equally important steps prior to cracking distillation. A concurrent pretreatment solid removal and dehydration and defueling process could also upgrade the quality and purity of oil products and increase the working efficiency.

Technical Process Description of Scada control waste engine oil distillation plant

- Feeding black waste oil from storage tank:Waste oil or pyrolysis oil will be pumped into the pretreatment tank for solid impurity and water removal.

- Dehydration&Defueling: Feed oil will be pumped into LGO stripping column for residual water and fuel oil separation. PurePath special design LGO stripping tower adopts oil gas separation technology, which could strip light gas oil almost completely.

- Cracking distillation and desulfurization process: Combining circulating heating and continuous distillation method, waste oil or pyrolysis oil will be evaporated continuous in distillation kettle. Oil gas distillates will be cracked by PurePath Formulated Cracking and Desulfurization catalyst to generate good quality diesel distillates.

- Continuous fractional distillation: Adopt gas-liquid mass transfer, combine with PurePath special design column temperature control method, a fractional column is designed to produce much purier and stable diesel.

- Refining for premium diesel product: The diesel oil product will be re-refined to improvve the oxidation stability and color.

Why PurePath?

1, Our products are the result of accurate and precise calculation.

2, Automatic and mechanized production, strictly quality control.

3, Make out design and production schedule ASAP reached an order.

4, Timely deliveries of consignment.

5, No agent processing, factory direct delivery, cost effective and competitive price.

6, Manufacturing engineers participate in the whole process of pre-sales and after-sales service.

7, Provide a full set of installation drawings, operation instructions, maintenance manuals and emergency handling manuals.

Plant Specification Of Scada control waste engine oil distillation plant

| Model No. | PPGT-LP-1 | PPGT-LP-2 | PPGT-LP-3 | PPGT-LP-4 | PPGT-LP-5 | PPGT-LP-6 | PPGT-LP-7 | PPGT-LP-8 |

| Items. | ||||||||

| Process Capacity MAX. | 2 TPD | 5 TPD | 10 TPD | 15 TPD | 20 TPD | 30 TPD | 50 TPD | 100 TPD |

| Heating Power | 17KGS LPG/20KGS FUEL OIL/230KWH/PER TON OF WASTE OIL | |||||||

| Power Consumption | 25KWH PER TONS OF WASTE OIL | |||||||

| Working Pressure | Atoms pressure | |||||||

| Heating Method | Fuel Oil/Natural Gas/LPG/Electricity | |||||||

| Heating Temp. | 30-420℃ | |||||||

| Voltage | 220/380/415V 50/60HZ | |||||||

| Noise | ≤60dB | |||||||

Performances of recycled diesel from Scada control waste engine oil distillation plant

Parameters Of Diesel Product From Scada control waste engine oil distillation plant

| PARAMETER | UNIT | METHOD | RESULT | ||||

| Flash Point PMCC | °C | ASTM D93-18a | 61 °C | ||||

| Water Content | ppm | ASTM D 6304-07 | 81 | ||||

| Lubricity, corrected diameter (ws 1.4) at 60°C § | µm | ASTM D6079-18 | 485 | ||||

| Ash Content | % wt | ASTM D 482-13 | <0.001 | ||||

| Sulphur Content | %wt | ASTM D4294-16e1 | 0.0046 | ||||

| Density at 15°C | kg/m3 | ASTM D1298-12b | 835.5 | ||||

| Pour Point | °C | ASTM D97-12 | -21 | ||||

| Cetane Index | ASTM D 4737-10 | 55.8 | |||||

| Viscosity Kin at 40°C | cSt | ASTM D445-17a | 3.8 |

High Lights Of Scada control waste engine oil distillation plant

•ECO Friendly: full set of tail gas processing line with scrubber and ultraviolet deodor system.

• Genuine continuous distillation: Equipped with unique fractionator for continuous process.

•Optional heating method to prevent fouling and higher heat efficiency.

•First-calss raw materials with ASME relations standard

•Thickness and material selection are after calculation by profession engineering software.

•Cooling and heat exchange area are after precising calculation by Apsen and ProII.

•Special waste oil from customer are doing pre-test and all properties are tested to give report in PurePath's professional laboratory.

Factory Show

Customer Visiting

Successful Project Show

Please do not hesitate to contact me.