SEED TECHNOLOGIES CORP., LTD.

- Annual Revenue 30000000-40000000 USD

- Employees 450~600

- Year Established 2006

- Manufacturer, Exporter

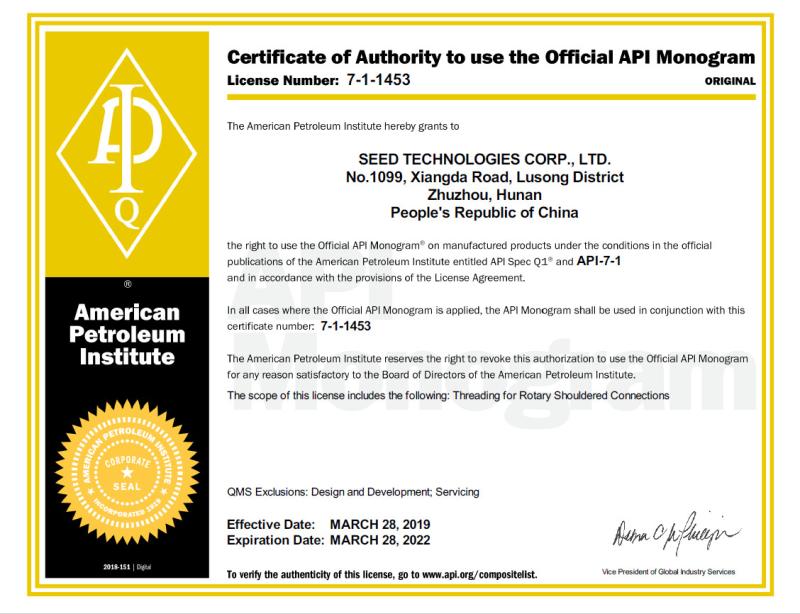

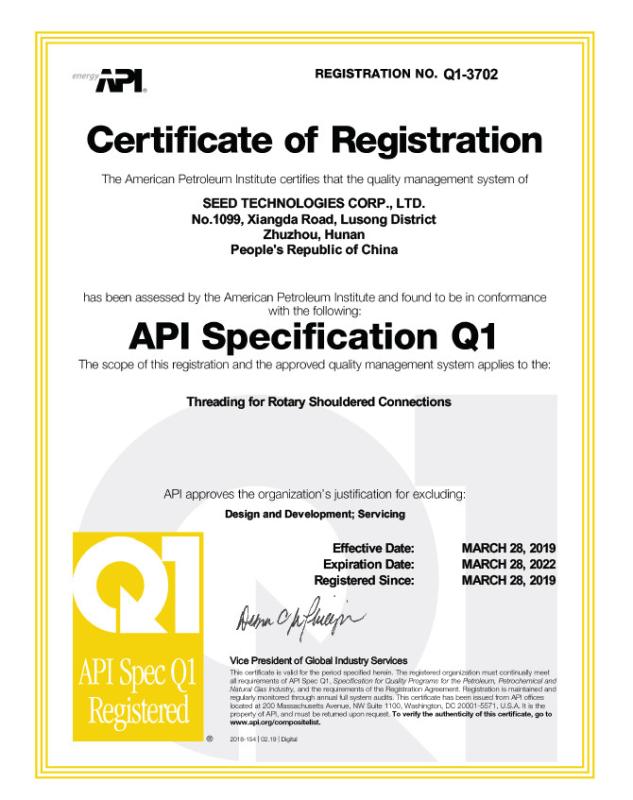

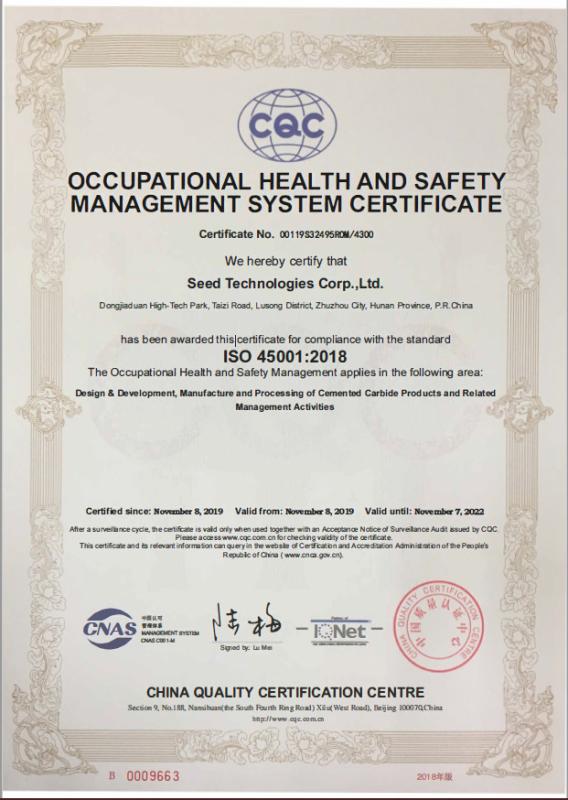

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Oil Industry Tungsten Carbide TC Radial Bearing 30 - 70HRC Hardness Aseeder

Oil Industry Tungsten Carbide TC Radial Bearing 30 - 70HRC Hardness Aseeder

Tungsten Carbide Radial Bearing is used as antifriction bearing for downhole motor. We have three different types from size 54 to size 286 for your choice (a total of 34 size). Besides, 4140 and 4340 alloy steel materials are most commonly used for the base material of our radial bearings. Custom steels are available upon customers request. Customer may also choose to use various tungsten carbide shape configurations including but not limited to rounds, rectangular, and grain style.

Materials Grade Reference As Below:

|

Grade |

Specification | Application of tungsten carbide | ||

| Density | TRS | Hardness | ||

| G/Cm3 | N/mm2 | HRA | ||

| ZY06X | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| ZY06 | 14.7-15. 1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| ZY08 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, non-metal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| ZY09 | 14.5-14.8 | ≥2300 | ≥91.5 | Qualified for low speed rough machining, milling titanium alloy and refractory alloy, especially for cut-off tool and silk prick. |

| ZY11C | 14-.3-14.6 | ≥2100 | ≥86.5 | Qualified for molding the drills for heavy-duty rock drill: detachable bits used for deep hole drilling, rock drill trolley etc. |

| ZY15 | 13.9-14.1 | ≥2020 | ≥86.5 | Qualified for hard rock drilling, steel bars with high compression ratios, pipe drawing, punching tools, core cabinet of powder metallurgy automatic molders etc. |

| ZY20 | 13.4-14.8 | ≥2480 | ≥83.5 | Qualified for making dies with low impact such as punching watch parts, battery shells, small screw caps etc. |

| ZY25 | 13.4-14.8 | ≥2480 | ≥82.5 | Qualified for making mould of cold heading, cold stamping and cold pressing used for manufacturing standard parts, bearings etc. |

Features:

1. Use 100% tungsten carbide raw material

2. Stable chemical properties

3. Excellent performance and good wear / corrosion resistance

4. HIP sintering, good compactness

5. Blanks, high machining accuracy / precision

6. OEM customized sizes available

7. Factory’s offer

8. Strict products quality inspection

| ASEEDER | Barrel Dimensions (inches) | |

| Radial Bearings | Diameter Range | Length Range |

| Inside Diameter (ID) | 3/4 - 12 | 1/2 - 30 |

| Outside Diameter (OD) | 3/4 - 12 | 1/2 - 30 |

Specialty precision machining Manufactory!

|

Type |

Welcome all inquiries, requirements and customized,OEM,ODM orders |

||

|

Processing |

According to your drawing or picture or samples |

||

|

Material |

Stainaless steel,iron,Aluminum,copper,CRS, |

||

|

Tolerance |

As drawing request |

||

|

Surface treatment |

Zn-plating,Ni-plating,Cr-plating,Black oxide,Sand blasting,anodzing, Hot-dip galvanizing, color zinc plating, powder coating, chemical oxidation, painting, electroplating, rust prevention |

||

|

Logo |

Laser carving or Oil injection (according to your logo file) |

||

|

Samples |

Acceptable. |

||

|

Surface Roughness |

As drawings |

||

|

Usage |

machinery, home appliances, electronic products, electric appliances,stationery, computers, power switches , Medical Equipment etc.Oil and Gas indurstry |

||

|

Machining equipment |

CNC machining center, grinding machine, milling machine, drilling machine,horizontal milling machine, chamfering machine, Metal Stamping ,CNC cutting machine etc. |

||

|

Advantage |

All the order can customize .Premium quality ,product with high precision. |

||

|

Delivery |

5-10 days for samples .20-30 working days for mass productions. |

||

|

Payment terms |

T/T, PAYPAL, L/C,NET 70, |

||

|

Port |

Guangzhou,Tianjing,Shenzhen,Shanghai,CHINA |

||