Customized 316l SS Steel Fabrication Chassis Stamping Die Components

Customized OEM Sheet Metal Fabricated Stainless Steel Chassis Die Stamping Part

Metal Stamping Parts

Xincheng Stamping manufacturers steels parts to meet the needs of your specific applications. Whether you need is a large, heavy part that requires thick walls for support, a small, intricate part, or a part that requires hardening and finishing after stamping, Xincheng Stamping has the capabilities to assist you.

We offer progressive stamping, and prototype stampings to ensure you receive the stamping product that best first your industry needs.

Operation

- Bending - the material is deformed or bent along a straight line.

- Flanging - the material is bent along a curved line.

- Embossing - the material is stretched into a shallow depression. Used primarily for adding decorative patterns. See also Repoussé and chasing.

- Blanking - a piece is cut out of a sheet of the material, usually to make a blank for further processing.

- Coining - a pattern is compressed or squeezed into the material. Traditionally used to make coins.

- Drawing - the surface area of a blank is stretched into an alternate shape via controlled material flow. See also deep drawing.

- Stretching - the surface area of a blank is increased by tension, with no inward movement of the blank edge. Often used to make smooth auto body parts.

- Ironing - the material is squeezed and reduced in thickness along a vertical wall. Used for beverage cans and ammunition cartridge cases.

- Reducing/Necking - used to gradually reduce the diameter of the open end of a vessel or tube.

- Curling - deforming material into a tubular profile. Door hinges are a common example.

- Hemming - folding an edge over onto itself to add thickness. The edges of automobile doors are usually hemmed.

| Processings | Stamping |

| Materials | Steel, Stainless Steel, Brass, Copper, bronze, Aluminum, Titanium, silicon steel, nickel plate etc |

| More Processing | Machining, Laser Cutting, CNC Bending, Plastic Injection, Welding, Riveting, Die/Mould Development etc |

| Tolerance | 0.01mm |

| Surface Treatment | Brushing, Polishing, Electrophoresis, Anodized, Powder Coating, Plating, Silk screen, Laser Engraving etc |

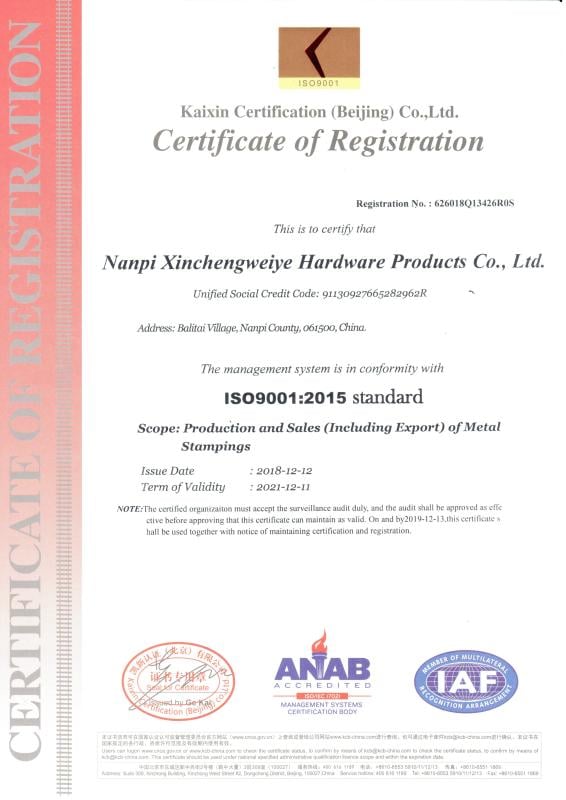

| Quality System Certificate | ISO 9001 |

| Lead Time | Depending on the customer drawings and requirements may be |

| QC System | Full inspection before shipment for every processing |

| Packaging | 1) Standard package |

| 2) Pallet or container | |

|

3) As per customized specifications

|

|

| Payment Terms | T/T , L/C , Paypal |

| Shipment Terms | 1) 0-100kg: express & air freight priority |

| 2) >100kg: sea freight priority | |

|

3) As per customized specifications

|

|

| One-Stop Service | Die/Mould development-Prototype-Production-Inspection-Surface treatment-Packing-Delivery |

Global efficient distribution, clean packaging bears the important responsibility of packing, protecting products and so on.

Our servies

| Product Scope | Surface Treatment | Material | Application |

| Stamping parts | Painting | Stainless steel | Mechanical equipment |

| Metal sheet | Powder coating | Cold rolled steel | Electrical facilities |

| CNC machining Parts | Zinc plating | Zinc alloy | Medical device |

| Lathe parts | Anodization | Aluminium alloy | Fitness equipment |

| Laser cutting | Sand blasting | Brass | Home appliance |

| Pipe fittings | Polishing | Titanium alloy | Automotive accessories |

| Mold/Die | etc | etc | Electronics |

| etc | Lighting |

Visit Website