Bus Bar Foil Laminates Ultrasonic Metal Welding Machine 20kHz 5000W

20kHz 5000W Ultrasonic Metal Wire Harness, Bus Bar, Foil Laminates Welding Machine

Description:

Ultrasonic metal welding machine welds non-ferromagnetic metal material workpieces through high-frequency mechanical vibration. In the welding process, one of the workpieces is fixed, and the other workpiece is cyclically vibrated on its surface at a frequency of 20/40kHz, and pressure is applied to the workpieces to form a firm bond between the workpieces, thereby achieving the welding effect . The entire welding process can be precisely controlled without generating excess heat on the metal surface, and the welding fastness is strong.

Product Perameter:

| Item | Ultrasonic metal weding machine |

| Frequency | 20Khz |

| Power | 2000W,3000W,4000W,5000W |

| Voltage | 220V |

| Application | For Metal spot wedling, cooper wire,Aluminum wire,Ting wire |

| Machine size | 500lx400wx230h mm |

| Generator size | 400LX280W220H MM |

| Generator | Ultrasonic Digital generator with touch screen |

| Welding area | 0.3-10m2 |

| Automatic Welding Time Range | 0.2-5second |

Features:

1. High stability: All-digital integrated circuit adopts high-performance anti-interference processor imported from the United States, while reducing the number of components, simplifying the hardware structure, and increasing the voltage stabilization function to improve the reliability and stability of the system.

2. Frequency automatic tracking: Digital frequency synthesis technology combined with digital phase-locked loop frequency tracking compound control technology can eliminate the drift of temperature, static load, processing area, tool wear and other factors. The shortcomings that conventional analog regulators are difficult to overcome, are conducive to parameter adjustment. , It is convenient to modify the program software, conveniently adjust the control scheme and realize a variety of new control strategies.

3. Powerful output: The use of IGBT power modules and the structure of a separately excited oscillating circuit make the output power more than 1.5 times that of a traditional self-excited circuit.

4. Stepless adjustment: UV can be increased or decreased instantly during the adjustment process, and can also be fine-tuned. It can effectively prevent the size of plastic parts from being perfectly welded, effectively restore shock and burns, and have defective product monitoring functions. It is more suitable for automated supporting use. Setting range 10%~100%

5. Intelligent protection and fault alarm prompt: mold current over protection, frequency offset protection, large protection. When the equipment fails, it will immediately stop working and give a corresponding prompt of the cause of the failure until the technician removes the failure.

6. The dynamic size adjustment realized by the intelligent intelligent neural network control technology is not affected by the input power voltage and load to affect the entire dynamic output.

7. A variety of welding modes are switched to make welding more refined, suitable for a wider range, and better welding effect.

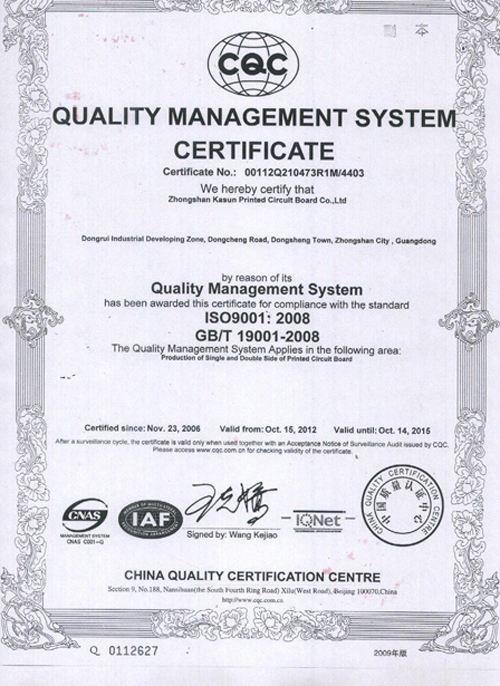

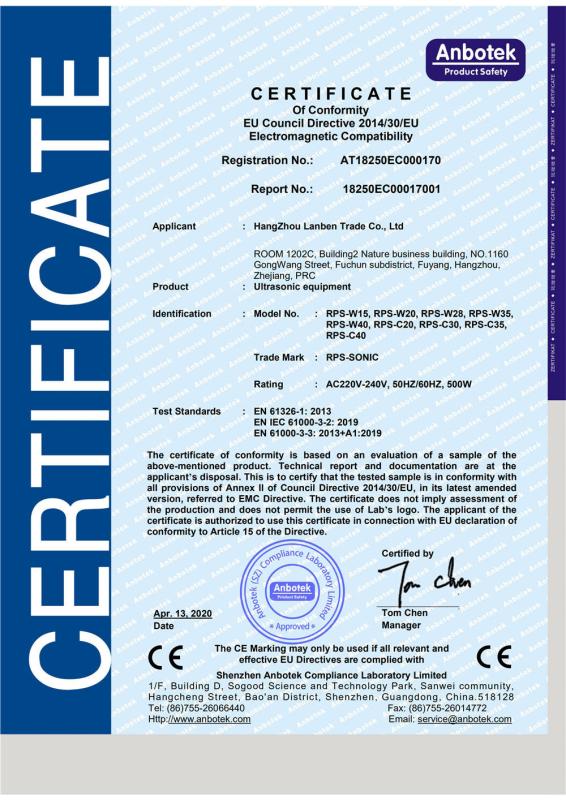

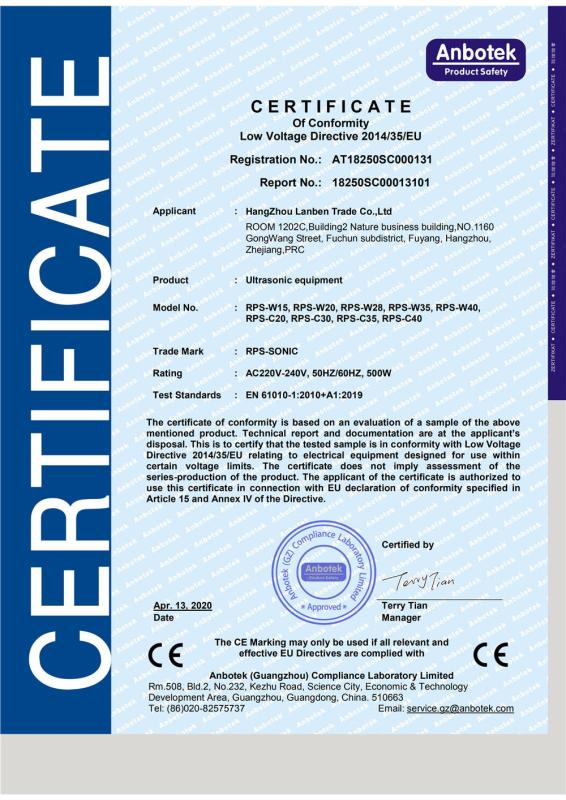

Product pictures: