Biomass Compost Organic Fertilizer Production Line Environmental Friendly

Environmental Friendly Biomass Compost Organic Fertilizer Production Line

1. Fermentation process: The first process of this production line is organic substance fermentation. In the production preparation stage, the compost will first be transported to the mixer for inversion and mixing to speed up the fermentation rate.

2. Crushing process: At this stage, the compost mass is pulverized using a pulverizer, and the subsequent granulation is prepared. However, if the compost fermentation is good and there is no agglomeration, this step can be omitted.

3. Ingredient quantification process: If a variety of materials need to be added to the formula, in order to improve processing efficiency and the accuracy of the proportion of each component in the formula, an automatic batching system can be used. The system includes multiple fixed-belt scales, but this step can be omitted if pure organic fertilizer is produced.

4. Granulation process: Disc granulators (drum granulators) are widely used for granulation of fertilizers. As the core step of this production line, our equipment can automatically screen out the particle shape that best suits the needs of our customers. The granulated fertilizer can delay the release of fertility and greatly reduce the number of artificial fertilization.

5. Drying process: In order to reshape the pellets and better storage, the humidity of the fertilizer should not exceed 14%. Tumble dryers are widely used for drying fertilizers.

6. Cooling process: In order to increase the hardness of the fertilizer particles, the drum cooler can meet this demand.

7. Screening process: Use a cylindrical sieve to screen out moderately sized particles. Too large and too small fertilizer particles will be re-pulverized and granulated.

8. Coating process: Use a drum coating machine to coat fertilizer particles to prevent the particles from sticking.

9. Packing process: As the last step of the production line, the packing process generally uses an automatic packer to quantitatively pack fertilizer into bags for sale.

10. Dust removal system: The dust generated in all processes will be collected and removed for dust and odor. 11. Ancillary facilities, the production line is equipped with belt conveyors and bucket elevators that connect various equipment.

Advantage:

1. Strong adaptability, suitable for the production of compound fertilizer and organic fertilizer with different formulas, different water contents and different concentrations.

2. Unique drying and cooling technology, which can fully dry and cool the materials, and can also perform secondary rounding and polishing on the particles.

3. Low temperature drying technology can produce ecological fertilizers rich in active microorganisms.

4. Advanced process design, reasonable equipment layout, compact structure and small footprint.

5. The tumble dryer is used as the host of the system, which has strong adaptability, simple operation, stable operation and reliability.

6. Can be equipped with fuel, gas, coal, biomass and other efficient automatic (or manual) hot air stoves for heating, reasonable design, high thermal efficiency, low drying costs.

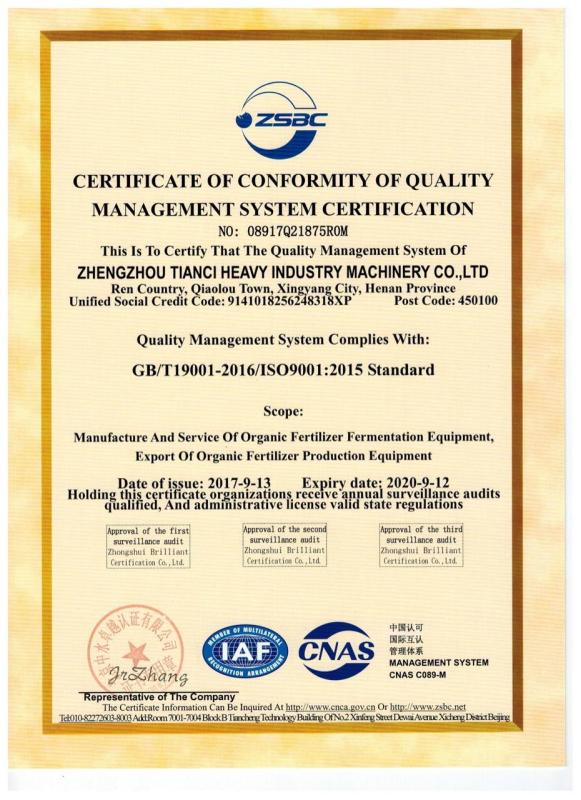

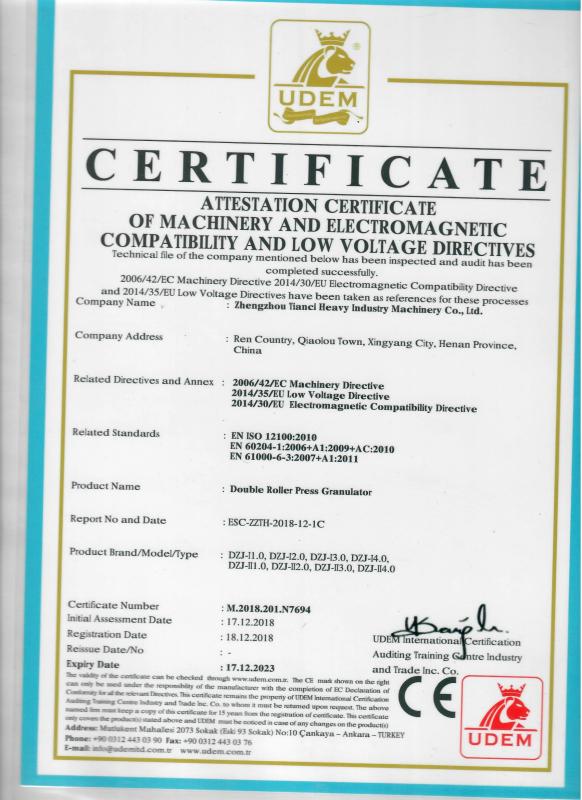

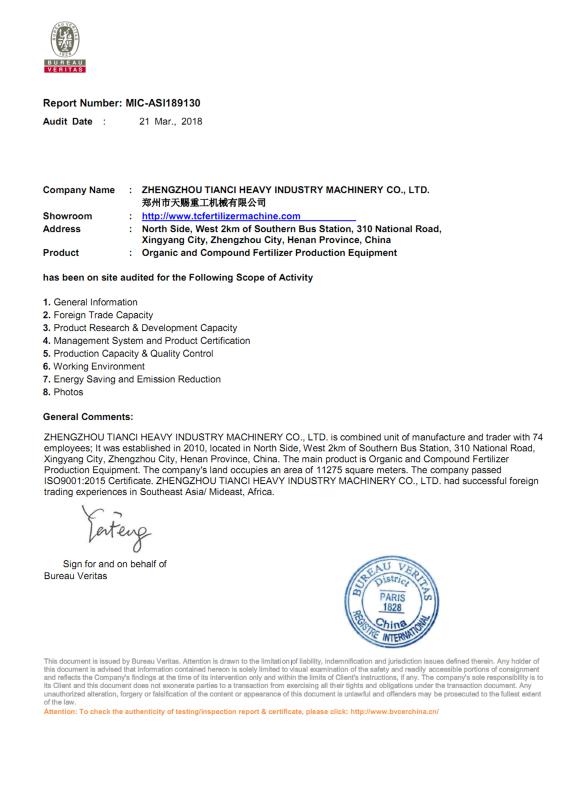

Company Introduction

Tianci Heavy Machinery Co., Ltd is a high-tech fertilizer machinery manufacturer which founded in 2001. Our company has 360 employees, covering an area of 80,000 square meters and having more than 180 professional processing equipment. In the past 20 years, we devote ourselves to producing organic and inorganic fertilizers-making equipment. Our equipment is sold to 22 countries, being the hot sale equipment in the global agricultural fertilizers industry. Being a large fertilizer machinery manufacturer, we provide customers with high added-value products and services, you can always get the complete solution of advice, designs, equipment, installation, training, emergency assistance, field assistance, spare parts, and routine maintenance. With years of constant development, we are always overall thinking at a high level and making better product management including quality, technology, testing, and production in international standards, We believe to create value for customers is to create value for ourselves, we are always moving forward to create the first-class technical products and services to reward customers.